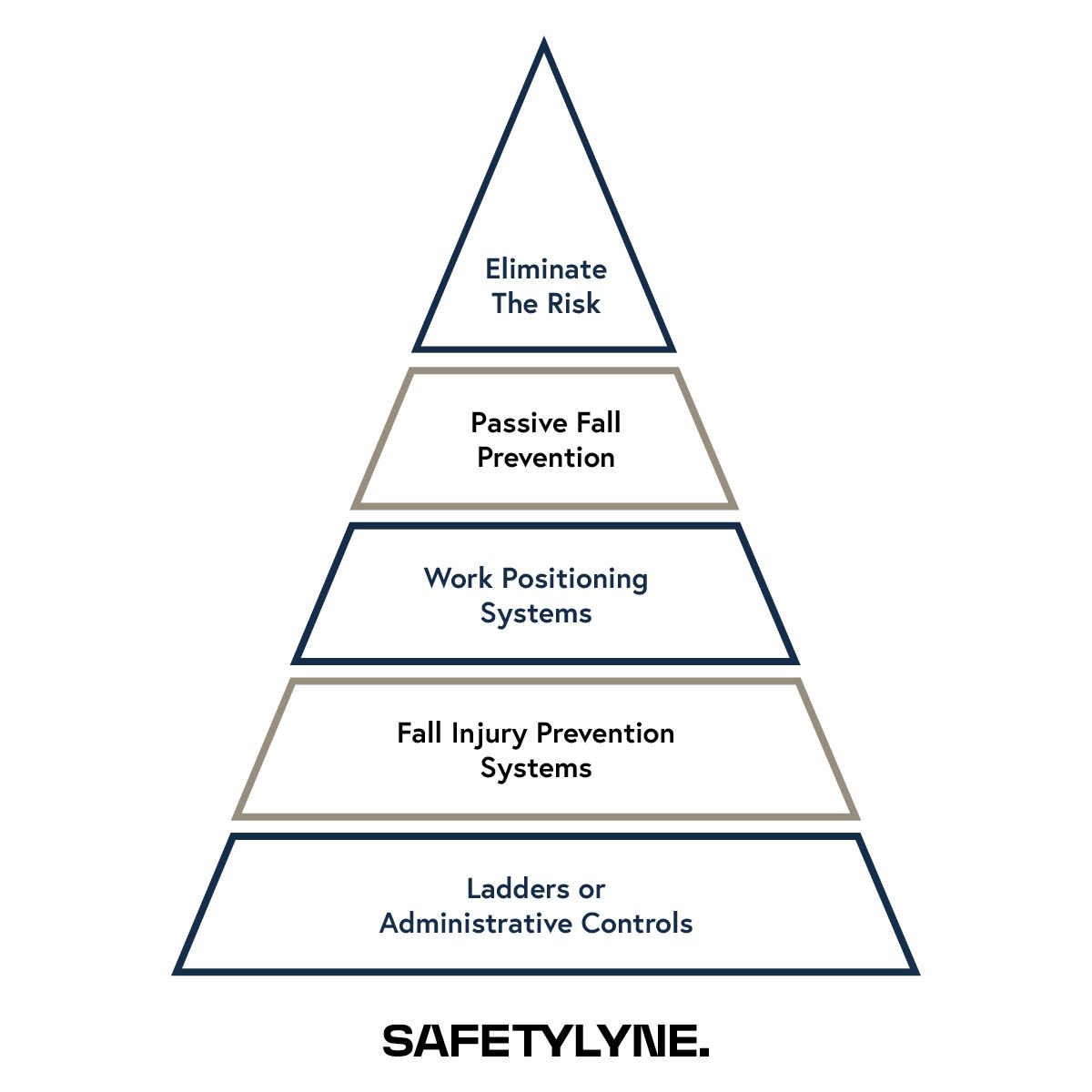

From Elimination to Administrative Controls

Ranked from the most effective to the least effective, a series of fall prevention solutions can be outlined as follows: Elimination, Passive Fall Prevention, Work Positioning Systems, Fall Injury Prevention and Administrative Controls. Each solution addresses fall hazards with varying degrees of efficacy, with elimination being the preferred approach.

The Hierarchy of Control

Level 1: Undertake the work on the ground or on a solid construction.

Level 2: Undertake the work using a passive fall protection device.

Level 3: Undertake the work using a work positioning system.

Level 4: Undertake the work using a fall injury prevention system.

Level 5: Undertake the work from ladders or implement administrative controls.

Level 1: Eliminate the Risk

Elimination involves identifying and mitigating the root causes of fall hazards to completely remove the risk of exposure. This could entail reevaluating procedures, practices, locations, or equipment to eliminate potential hazards. For instance, relocating HVAC equipment from rooftops to ground level or equipment rooms can eliminate fall hazards associated with working at heights.

Conducting thorough site surveys and engaging height safety specialists during the design phase of new construction projects can help identify and eliminate potential fall hazards. Accessing maintenance areas via solid structures like stair towers, fixed ladders and guardrail systems incorporated with platforms, walkways and plant decks further minimises risk.

Level 2: Passive Fall Prevention

Passive fall prevention measures offer a higher level of safety by reducing the likelihood of errors compared to relying solely on personal protective equipment (PPE). While initial costs may be higher, passive protection solutions are often more cost-effective in the long term.

Installing

guardrails

and

void protection

are examples of passive fall prevention measures that provide physical barriers against falls.

Level 3: Work Positioning Systems

Work positioning systems prevent falls by restricting a worker's range of movement using PPE. Unlike fall injury prevention systems, work positioning systems ensure that a fall cannot occur, thereby eliminating the need to mitigate free fall distance and reducing risks associated with secondary injuries and rescue operations.

Utilising fall restraint rail systems , anchor points with shock absorbing lanyards, and harnesses helps establish effective work positioning systems, enhancing worker safety and simplifying rescue procedures.

Level 4: Fall Injury Prevention System

Fall Injury Prevention systems are designed to stop a fall once it occurs, within acceptable force and clearance parameters. However, they inherently carry higher risks compared to work positioning systems, as they require swift intervention to prevent contact with surrounding structures or the ground.

Utilising fall injury systems such as catch nets, catch platforms and individual fall arrest systems providing comprehensive training on their use is crucial to minimise risks associated with falls. Training should encompass both fall restraint and fall arrest techniques, ensuring workers are equipped to handle various fall scenarios.

Level 5: Ladders or Administrative Controls

The last resort for working safely at height encompasses

ladders

and administrative controls. Administrative controls involve implementing work practices or procedures to raise worker awareness of fall hazards. While they can contribute to risk reduction, administrative controls are considered the least effective method as they lack physical safeguards.

Employing safety monitors, warning lines, designated areas, and control lines are examples of administrative controls. However, it's essential to note that administrative controls should complement, rather than replace, more robust fall protection measures. Compliance with WHS regulations governing administrative controls is imperative, and thorough understanding of applicable jurisdictions and regulations is necessary for effective implementation.

The Safetylyne Way

At Safetylyne, we establish and develop cutting-edge roof safety and maintenance access solutions for our clients' evolving needs. We are your trusted partner offering specialised insights into proprietary engineered systems and custom access solutions.

Our mission is to simplify the complexities encompassing access solutions.

Get in touch with Safetylyne, experts in height safety, today to explore tailored solutions for your height safety and maintenance access needs.

info@safetylyne.com.au | 07 2112 9701

Learn more about managing the risk of falls

here.

IN SITU

Site by Wülfe Marketing

All Rights Reserved

We improve our products and advertising by using Microsoft Clarity to see how you use our website. By using our site, you agree that we and Microsoft can collect and use this data. Our privacy policy has more details.