Fall Restraint Overhead Rail Systems

Fall Restraint Overhead Rail System

Safetylyne’s innovative Fall Prevention Rail provides continuous, secure attachment for multiple users working at heights.

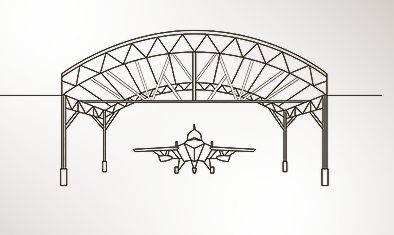

It is an effective fall protection where overhead anchorage is essential, eg. airport hangars, workshops, maintenance bays, industrial access areas, etc.

Safetylyne’s Fall Restraint Overhead Rail System is a purpose-engineered overhead access solution designed to provide predictable, continuous fall protection in complex environments.

Developed in-house, this rigid overhead rail system supports controlled movement for multiple users working at height, making it well-suited to aircraft hangars, maintenance bays, industrial facilities, and high-bay service environments.

Overhead Rail Systems Features

- Full Compliance. Adheres to all relevant Australian standards, all overhead access systems are compliant with AS/NZS 1891.2.

- Uninterrupted Movement. Allows multiple workers to move freely and safely on elevated areas with potential fall hazards (eg, the top of the airplane or machinery).

- Minimal Deflection. Ensures minimal movement during a fall, enhancing safety.

- Versatile Applications. Suitable for fall arrest and abseil (rope access).

- High-Quality Materials. Manufactured in Australia using high-grade aluminium and stainless steel.

- Flexible Mounting Options. Can be mounted on various surfaces, including purlins, metal or concrete decks, ceilings, and walls.

- Aesthetic and Durable. Neat, unobtrusive design with optional powder coating.

Predictable coverage for hangars and high-bay facilities

Rigid rail behaviour allows fall protection to be designed with confidence.

The system reduces fall distance by removing slack found in traditional cable systems, enabling safe overhead access where clearance is limited.

This approach supports maintenance activities across wing surfaces, leading edges, fuselages, and elevated service zones without compromising compliance.

As a result, the system performs reliably as an overhead rail for hangars, workshops, and industrial environments where predictable fall behaviour is essential.

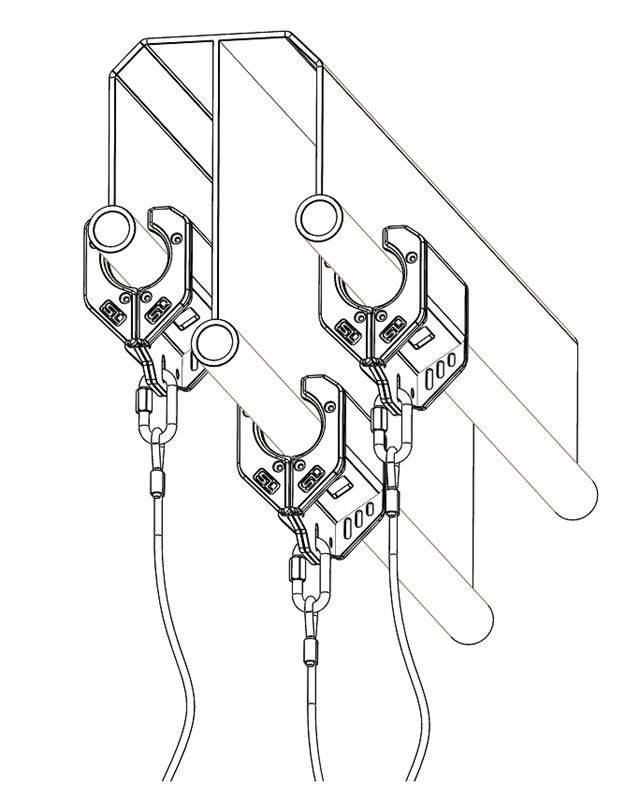

Overhead Rail Safety Systems

Our overhead rail systems feature high-strength, lightweight aluminium rails that can span up to 6 meters between structural supports.

These systems include sealed bearing trolleys with lateral stabilising bearings, allowing effortless movement for multiple users simultaneously.

Complying with AS/NZS1891.2:2001 and AS/NZS1891.4:2009 standards, our locally manufactured systems ensure effective safety and reliability.

Overhead Rail Systems for Fall Arrest

Our overhead rail fall arrest systems provide effective, unrestricted fall protection for multiple users working above a designated zone. When used with an inertial reel or self-retracting lifeline, these systems maintain the user in a fall restraint position, reducing the risk of mid-air suspension. These rails can be mounted to various surfaces, ensuring compliant height safety where other systems might be impractical.

Multi-user access with continuous attachment

The overhead access rail system is designed to support efficient, coordinated maintenance.

Clear spans of up to 6 metres reduce structural congestion while supporting multiple users on a single run, subject to engineering assessment. Integrated rail configurations allow technicians to pass one another without disconnecting, maintaining 100% tie-off throughout the task.

This capability supports higher productivity while maintaining full fall prevention rail compliance.

Materials selected for demanding environments

Systems are manufactured in Australia using marine-grade aluminium and stainless steel hardware selected for durability, corrosion resistance, and aviation safety.

Anodised aluminium removes the risk of coating degradation and Foreign Object Debris, making the system suitable for sensitive environments such as aircraft maintenance facilities, coastal sites, and heavy industrial operations.

All overhead rail safety systems comply with AS/NZS 1891.2 and AS/NZS 1891.4.

Designed for inspection, rescue planning,

and future change

Annual inspection and recertification are supported in line with AS/NZS 1891.4.

The modular, bolt-together architecture allows future expansion or reconfiguration without hot works. Where required, the system can form part of a broader rescue rail strategy when integrated into a site-specific emergency response plan.

This future-ready design supports long-term asset flexibility as facility layouts or equipment profiles change.

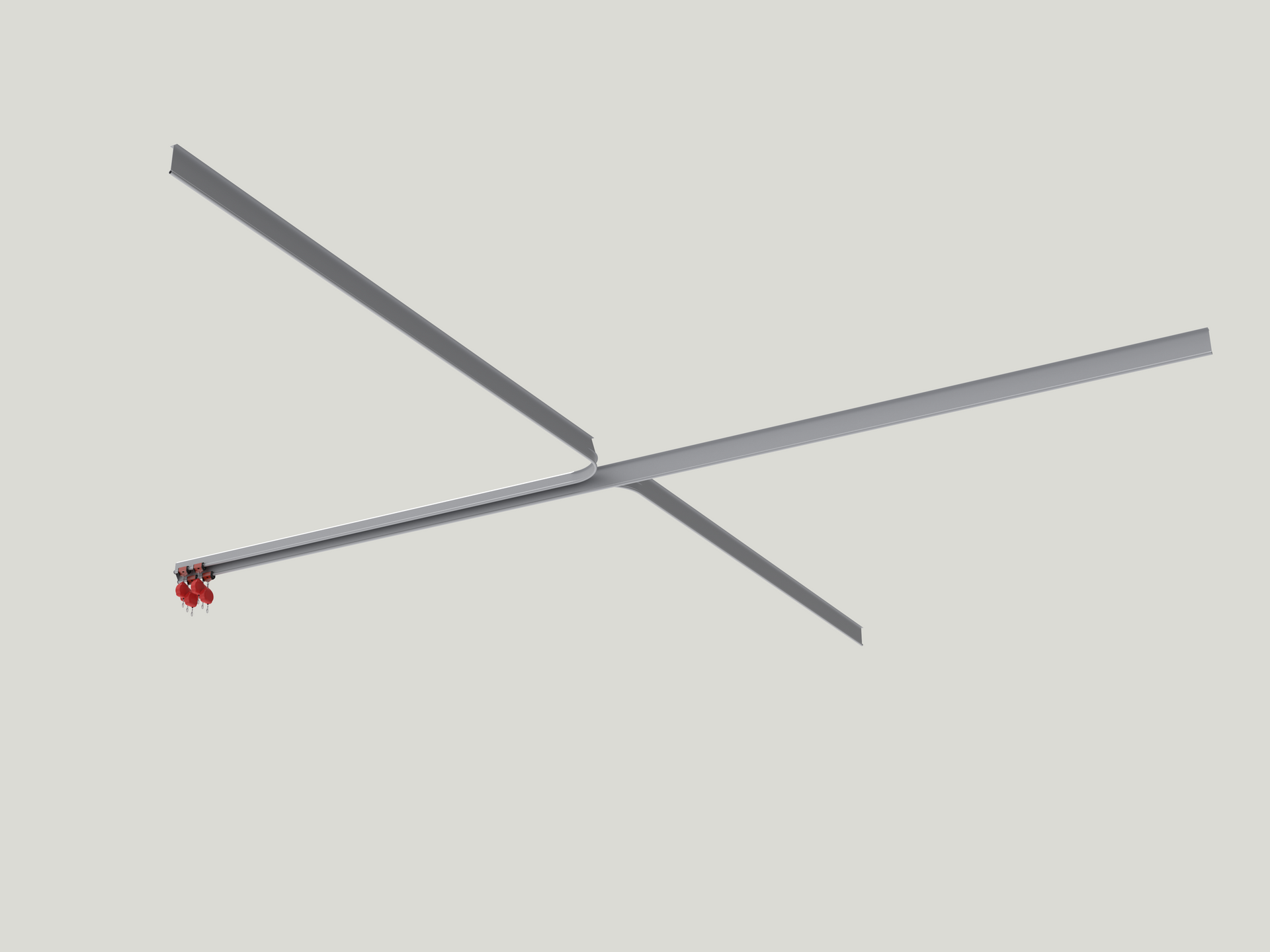

System configurations

Safetylyne designs and engineers overhead rail systems to suit specific operational needs, including:

- Single overhead rail systems

- Twin overhead rail systems

- Multi-rail and tri-rail overhead access systems

Each configuration is developed to suit user numbers, structural constraints, and maintenance workflows.

Engineered integration with existing structures

Every overhead rail system is engineered to work with the building, not against it.

Low-profile aluminium rails integrate within roof truss zones, maintaining clearance from bridge cranes, services, and hangar doors. For facilities with complex layouts, segmented rail junctions maintain a continuous fall restraint rail path across moving doors and transitions.

Non-destructive fixing methods allow the system to attach to existing structural members without drilling or welding, preserving structural certification under AS/NZS 1170.

Additional Features

+ Safe, continuous movement

Overhead Rail Systems let staff work at height while moving freely and safely. They prevent falls and protect people working below.

+ Full system integration

Workers can move from vertical to horizontal positions on one continuous system without disconnecting. The system incorporates self-retracting lifelines (SRLs) for added safety and ease of movement.

+ Efficient design

Minimal intrusion into the workspace, high load capacity, and clear floors improve both safety and efficiency.

+ Flexible installation

Suitable for a wide range of structures and applications.

+ Custom options

Systems can be tailored to specific site requirements.

The Tri-Rail Fall Restraint System is a proprietary fall arrest and rope access solution designed for environments where consistent fall protection is essential.

Designed for extended work areas, the system features large spans that ensure continuous and secure attachment for harness connections. Its rigid rails provide uninterrupted mobility, allowing multiple operators to work safely and efficiently at the same time.

Typical applications include atrium maintenance, aircraft wing and fuselage repairs access, tail cleaning, and cockpit inspections.

The Tri-Rail System helps to reduce maintenance time, increases efficiency, and supports faster work turnaround by enabling several workers to operate on different sections of an aircraft or structure at the same time.

This access system can accommodate complex architectural designs, including corners and irregular curves. Manufactured from marine-grade aluminium and 304 stainless steel, the system is lightweight, corrosion-resistant, and built to perform in demanding or highly corrosive environments.

With a 25-year materials warranty and 2-year installation warranty (subject to regular inspections), the Overhead Rail Fall Arrest System provides long-term reliability and peace of mind. It is a robust choice for industries ranging from aviation and mining to large-scale vehicle maintenance.

For more specialised aviation applications and custom aircraft maintenance solutions, visit our Aviation Height Safety Systems page.

Industry information - Civil Aviation Safety Authority

Why Safetylyne Access Systems Are the Smart Choice

We engineer and manufacture the exclusive Overhead Maintenance Access System, designed to support up to three maintenance personnel at once.

It delivers unmatched safety, efficiency, and reliability for complex access requirements.

Our comprehensive services include the design, installation, fabrication, and certification of customised overhead rail fall arrest systems, and a wide range of height safety systems tailored to meet specific needs of your industry.

Our teams in Melbourne, Sydney, Brisbane, and across Australia design every system to meet the highest standards.

The Tri-Rail System is designed for large-scale maintenance access, including Boeing aircrafts (Dreamliner and other models), E-Jets, Bombardier planes, seaplanes, helicopters, and other planes.

Our overhead fall arrest systems are proudly Australian Made Certified

Additional airplane maintenance access systems also feature other height safety systems:

- Airplane Maintenance Access Stair Platforms

- Helicopter Maintenance Access Solutions

In accordance with AS/NZS 1891, the 30° pendulum cone defines the safe working radius from an anchorage point. By positioning the overhead service maintenance rail at the highest practical level, the system maximises usable coverage while maintaining a compliant and predictable arrest path.

Unlike cable-based overhead harness rail systems, the rigid rail profile eliminates sag and dynamic deflection. The pivot point remains fixed, enabling accurate swing-drop calculations and improved certainty of clearance around aircraft, machinery, and work platforms

Problem-Solving Applications of Overhead Rail Systems

- Airplane Maintenance

Ensuring compliance with height safety regulations, our overhead rail systems provide secure access from above, which is essential for the maintenance, cleaning, and upkeep of aircraft.

These systems allow workers to remain secure even on uneven surfaces at height.

- Mining

In the mining industry, our overhead rails offer safe and efficient access for equipment maintenance and operational inspections, height access above machinery and elevated areas access, mining mills overhead maintenance access, and other types of height safety. This height safety system addresses the unique access challenges of working in mining environments. Overhead rail can solve various height safety in mining.

- Large Vehicle Wash Platforms

Our overhead rail fall arrest systems provide secure and unrestricted access, enhancing both safety and efficiency for maintenance and cleaning of large vehicles and machinery. Suitable for track wash and maintenance bays.

Other Applications For Overhead Rail Systems:

- Food manufacturing and Overhead rail system for meat processing.

- Construction Sites. Provides safe access for workers during high-rise building projects.

- Warehouse Operations and Maintenance. Ensures safety for tasks performed at height, such as lighting maintenance and inventory management.

- Manufacturing Facilities. Facilitates safe access to elevated machinery and equipment for maintenance and inspections.

- Heavy Vehicles Maintenance Access in Mining

FREQUENTLY ASKED QUESTIONS

See how Safetylyne solved aircraft maintenance access challenges by installing rigid overhead rail in the aircraft hangar.

CONTACT OUR HEIGHT SAFETY EXPERTS TODAY