Understanding Fall Arrest and Fall Restraint Systems

Safety should be the top priority in any work environment, especially in industries where employees work at heights.

Fall arrest and fall restraint systems are the main components in ensuring worker safety and preventing accidents.

Let's see the differences between these systems, helping you make safe decisions for your workplace.

Fall arrest systems are designed to stop a worker's fall in progress. These systems are essential for situations where there is a risk of falling from a height.

If the workers perform their tasks next to the edge, the system catches them before they fall.

The fall arrest system allows you to move freely within a designated area, and it only activates once you fall. This safety system should be designed to stop you before you get to a lower level or the ground.

Components of Fall Arrest Systems

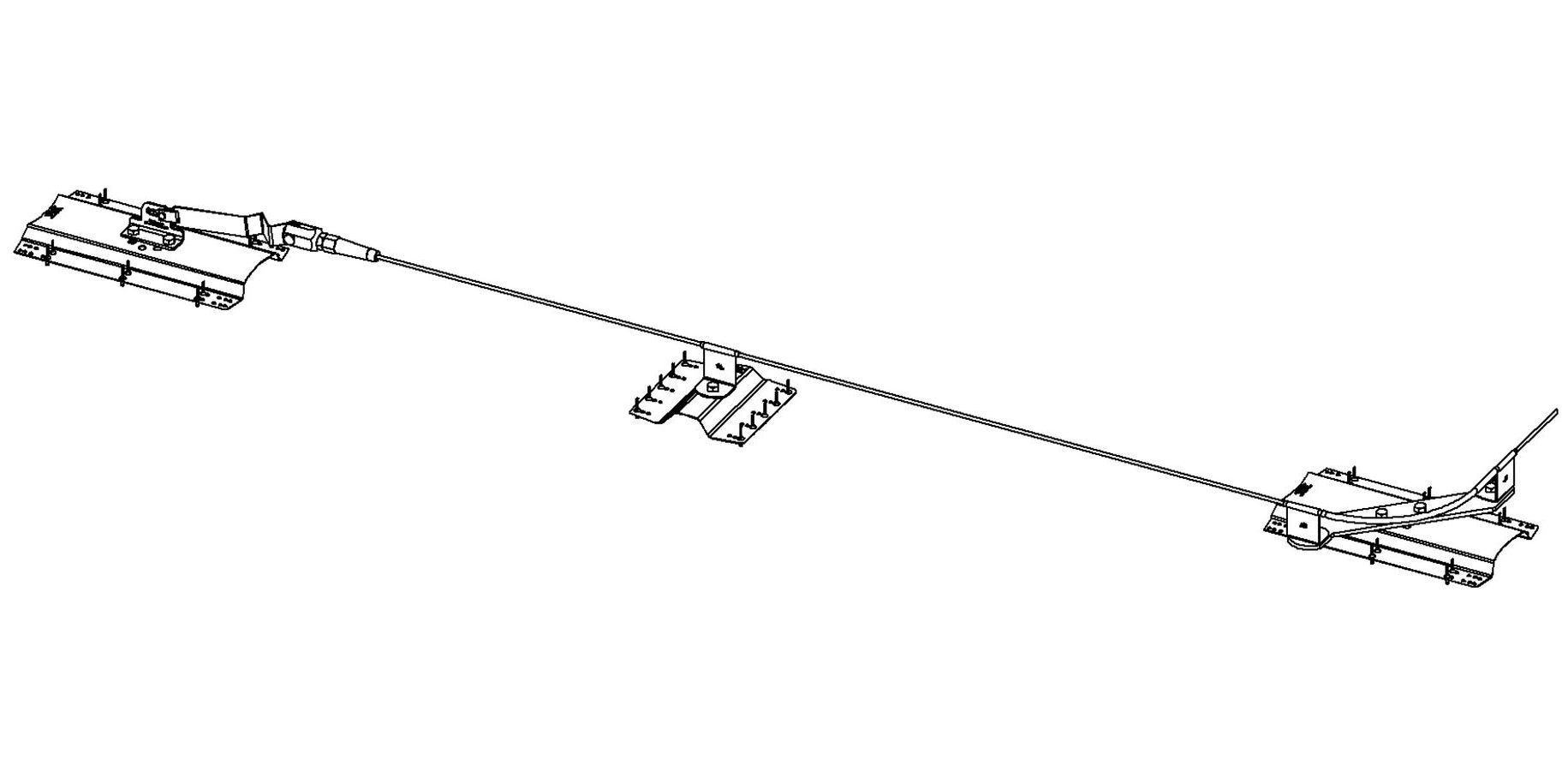

A typical fall arrest system includes:

- Anchor Point - A secure point where the system is attached. It must be strong enough to withstand the forces of a fall.

- Body Harness - Worn by the worker, distributing the force of the fall across the body.

- Connecting Device - Often a lanyard or a self-retracting lifeline that connects the harness to the anchor point.

When to Use Fall Arrest Systems

Fall arrest systems are used when workers are performing tasks at heights where a fall hazard exists, such as on rooftops, ladders, or scaffolding.

These systems are vital when it is not possible to eliminate the fall hazard or use other means to prevent a fall.

What Are Fall Restraint Systems?

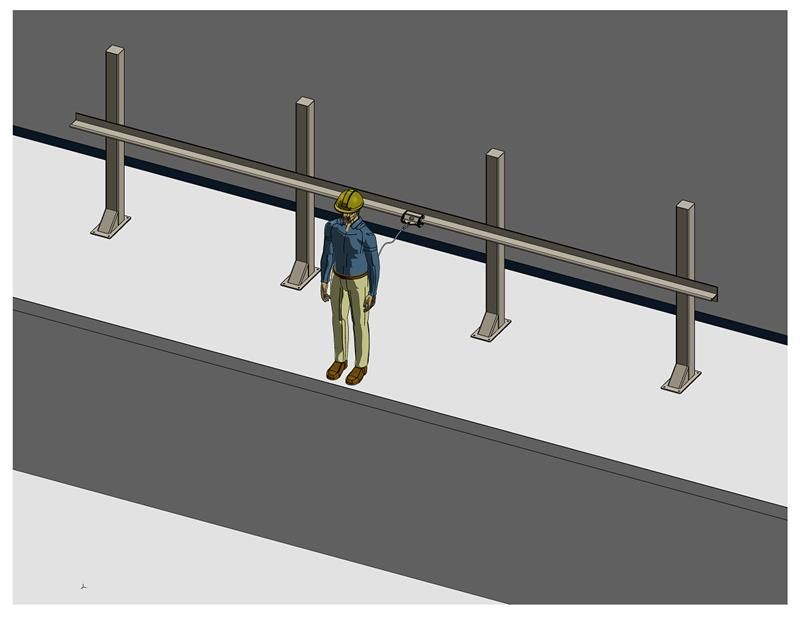

Fall restraint systems, unlike fall arrest systems, are designed to prevent a fall from occurring in the first place. These systems restrict a worker’s movement to prevent them from reaching an area where a fall could happen.

Components of Fall Restraint Systems

A fall restraint system typically includes:

- Anchor Point - Similar to fall arrest systems, it provides a secure attachment.

- Body Harness - Designed to keep the worker from reaching the fall hazard.

- Restraint Line - A fixed-length line that limits how far the worker can move.

When to Use Fall Restraint Systems

Fall restraint systems are ideal for situations where workers need to be near a fall hazard but can perform their tasks without the need to approach the edge.

Examples include maintenance work on flat rooftops or working near skylights.

Fall Arrest vs Fall Restraint: Key Differences

Understanding the differences between fall arrest and fall restraint systems is critical for safety managers, building maintenance managers, and all workers performing tasks on elevated areas.

Here are some key distinctions:

- Purpose - Fall arrest systems stop falls in progress, and fall restraint systems prevent falls from occurring.

- Mobility - Workers using fall arrest systems can move around freely, but the system catches them if they fall. Fall restraint systems limit movement to prevent reaching the hazard.

- Application - Fall arrest systems are used when a fall risk can’t be completely removed, while fall restraint systems are designed to stop workers from reaching the edge or hazard in the first place.

What does it mean for you:

+ Use fall arrest - when a fall can’t be avoided.

+ Use fall restraint - when workers can stay clear of the hazard altogether.

Implementing effective fall protection systems involves several steps:

1. Assess the Work Environment

Conduct a thorough assessment of the workplace to identify potential fall hazards. Consider areas where workers are exposed to heights and determine whether fall restraint or fall arrest systems are more appropriate.

2. Choose the Right System

Select the system that best fits the work environment and tasks. If possible, use fall restraint systems to prevent falls. If not, ensure that fall arrest systems are properly installed and maintained.

3. Train Employees

Provide comprehensive training for employees on the use of fall protection systems. Training should cover how to properly wear harnesses, connect to anchor points, and inspect equipment.

4. Regular Inspections and Maintenance

Implement a routine inspection and maintenance schedule for all fall protection equipment. Check for wear and tear, ensure all components are functioning correctly, and replace any damaged parts if needed.

For a professional height safety review, talk to Safetylyne about a site safety audit.

Our team can assess your height safety setup, identify any gaps, and recommend the most effective solutions for your site.

5. Stay Compliant with Regulations

Stay updated with local and national safety regulations on fall protection.

Ensure that all systems and practices comply with these standards to maintain a safe work environment.

By understanding the differences and implementing the right systems, safety managers can significantly reduce the risk of accidents, create a safer workplace, and maintain compliance.