Height Safety Management

A well-run height safety program protects workers, reduces operational risk, and helps your project stay compliant from day one.

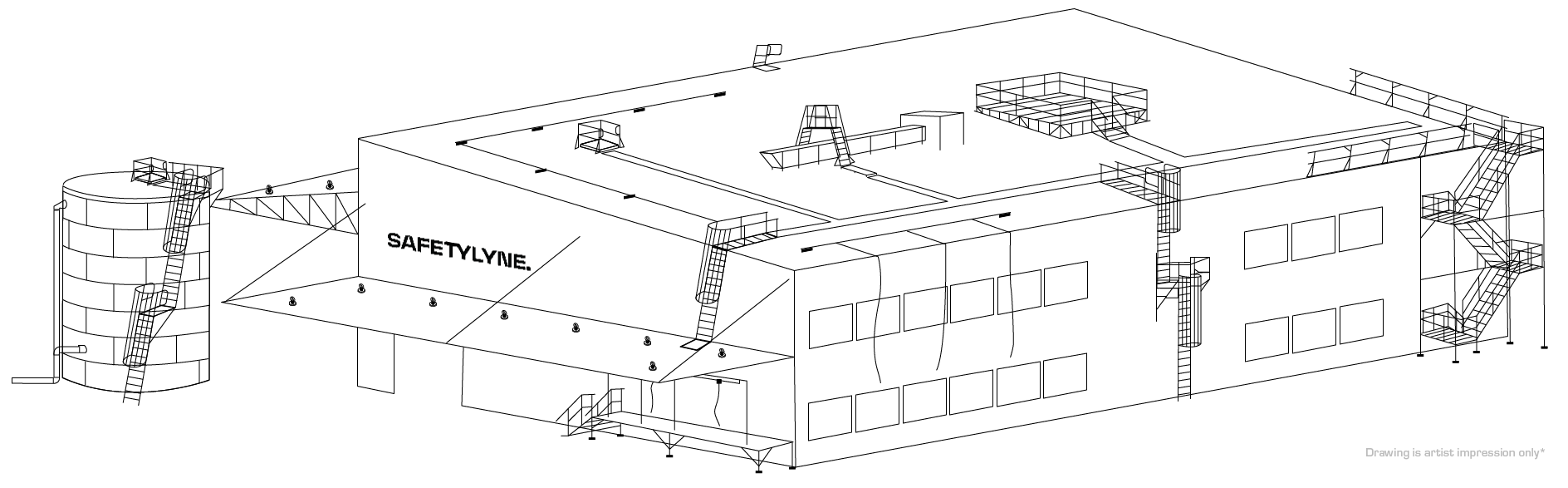

Strong systems start long before anyone climbs a ladder or steps onto a roof. They begin with planning, informed design decisions, and a structured approach to managing hazards across the life of the building.

This page outlines practical steps you can use today. You can link deeper into detailed design guidance or full height safety audits where needed.

Risk Management: Building a Safer Structure From the Start

Effective risk management means identifying hazards early and removing or minimising them before work begins.

Strong height safety planning includes:

+ Clear identification of working-at-height tasks

Every plant platform, roof access route, suspended walkway, and maintenance point should be mapped and assessed. This gives designers and building managers a complete view of exposure.

+ Selecting the right type of access system

Ladders, stairs, hatches, walkways, platforms, abseil points, and overhead rail systems must suit the activity and comply with

height safety regulations.

+ Understanding standards and

hierarchy of control

Guardrails, walkways, engineered anchor systems, and restricted-access platforms each play a specific role. Knowing when each is required prevents compliance issues during certification.

+ Planning safe traffic flow

Workers should not be forced into narrow gaps, fragile surfaces, congested plant layouts, or roof areas with limited visibility. Good layout design directly reduces fall incidents.

Managing Height Safety at the Workplace

Once a building is operating, risk management becomes an ongoing responsibility. Strong safety systems rely on consistency, clarity, and documented processes.

+ Routine inspections and

recertification

Access systems need scheduled inspections, and building managers need simple, structured reporting to catch issues before they escalate.

+ Controlling who enters roof spaces and plant rooms

Avoid unsupervised or unrestricted access. Use clear signage, locked access points, and defined permissions to keep people safe and compliant.

+ Training and competency

Workers should know how to use fall arrest gear, overhead rails, anchors, ladders, and platforms correctly. Training also reduces the likelihood of emergency callouts and unplanned downtime. Safetylyne provides height safety systems use training as a part of our project delivery.

+ Managing contractors

Every contractor stepping onto the site should meet your safety expectations. Clear induction, safe-work procedures, and documented equipment checks protect everyone involved.

+ Responding to changes in equipment or layout

New mechanical units, solar arrays, refrigerant lines, or cable trays often change access needs. Regular reviews keep the system aligned with the building’s evolving requirements.

Managing Height Safety at the Design Stage

Design decisions have the biggest impact on long-term safety. Early coordination between architects, designers, engineers, fire consultants, and height safety specialists leads to cleaner, safer, and more cost-effective outcomes.

Good height safety design practice involves:

- Placing plant and equipment where safe access is achievable without complex systems

- Integrating stairs, platforms, ladders, and walkways into the structure rather than forcing retrofits

- Ensuring the roof layout supports compliant travel paths and clear fall-protection zones

- Using structural elements that support future maintenance loads

More Areas to Strengthen Your Height Safety And Workplace Safety Program

Safe Access Planning

Stairs, hatches, platforms, and fixed ladders each have specific compliance requirements and height limits. Poor access planning is one of the most common causes of non-compliance.

Confined Spaces & Ceiling Void Access

Ceiling cavities, cold-store roof spaces, and mechanical mezzanines often combine height hazards with limited space and poor visibility. Smart design and clear access planning can improve classification and reduce risk for maintenance teams.

Documentation & Compliance Pathways

Clear compliance pathways include inspection reports, load ratings, maintenance manuals, and product specifications kept in one place for audits or council requirements.

Emergency Access & Egress

Safe escape routes, protected access points, and non-slip surfaces become critical when systems are used during emergencies.

Clear coordination with fire engineers helps to make sure your access systems don’t interfere with evacuation routes or the building’s fire-cell layout.

Integration With Trades AND OTHER MAINTENANCE TASKS

Mechanical, electrical, solar, refrigeration, façade access, and structural trades all influence height safety.

Early planning and integration will help you prevent clashes, obstructions, and last-minute changes that reduce safety and increase cost.