Anchor Points

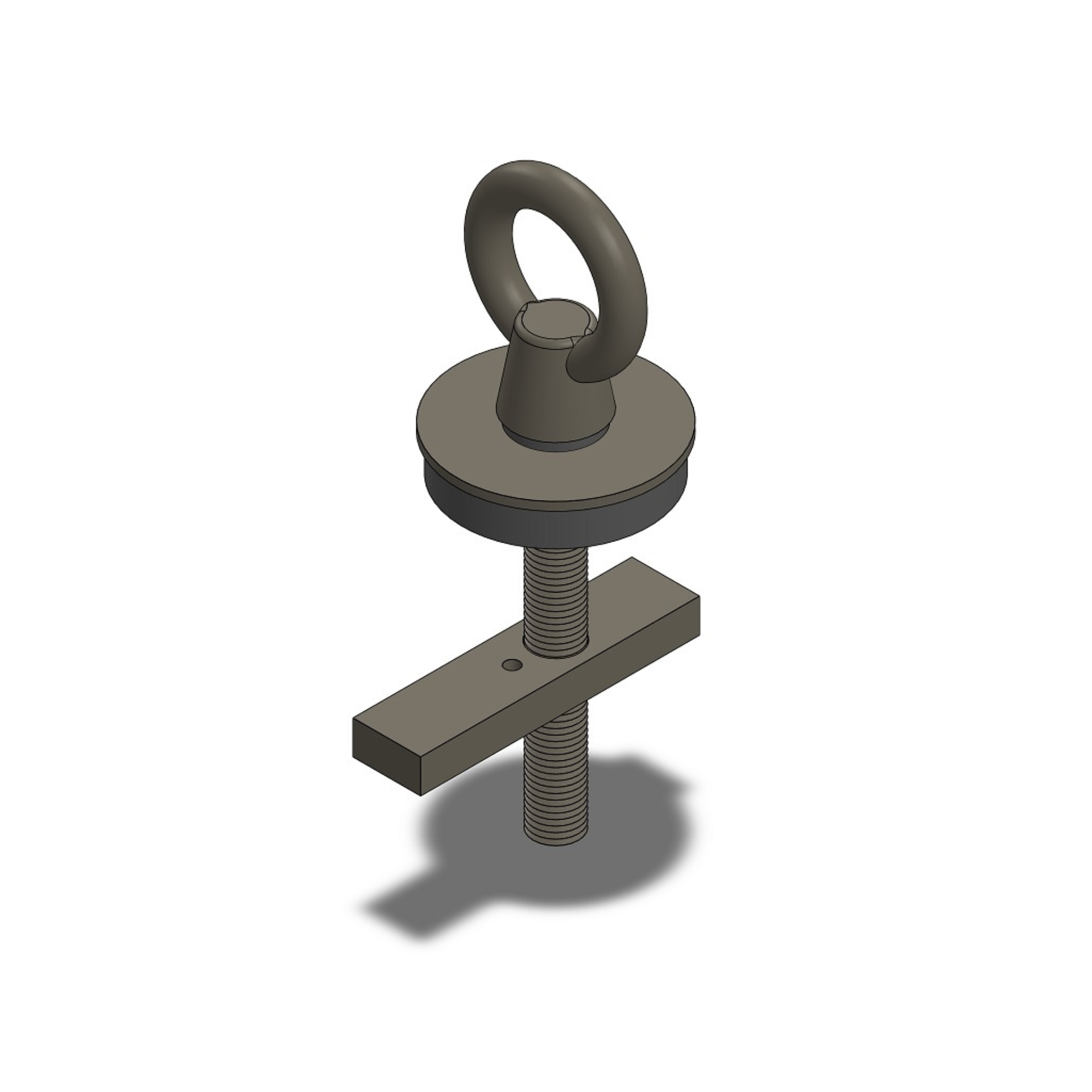

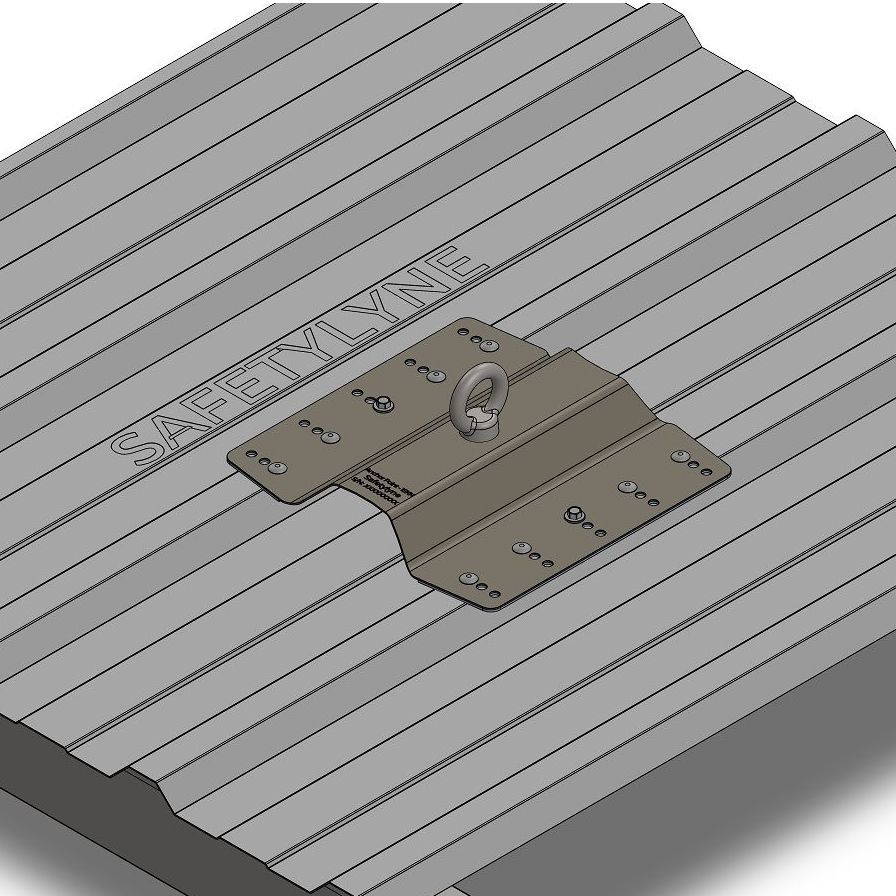

Safetylyne anchor points create secure connection points on roof sheets, giving maintenance teams safe and compliant access for inspection or service work.

Each

fall restraint system is engineered for the site, ensuring maximum safety and minimal user risk.

ANCHOR POINTS FOR FALL PROTECTION AND FALL ARREST

When Your Building Needs Permanent Anchor Points

If your roof has equipment, walkways, or areas that need regular maintenance, you’ll need anchor points to keep workers safe.

Anchor points let workers clip on their safety harness while cleaning, repairing, or inspecting roof areas.

They’re especially important near roof edges or around equipment like HVAC units, where guardrails can’t be used.

Installing the right system keeps maintenance safe and helps your site meet

height safety regulations.

Before installing your roof safety systems, it is important to understand how anchor points work and what keeps them compliant.

- Roof Anchor Points Types

Different roof anchors suit different roof materials and specific structures.

- Load Requirements

Each anchor must meet strict load requirements to handle the force of a fall.

Using tested and certified systems ensures they’ll perform when needed.

- Inspection and Maintenance

Anchor points require regular checks to stay safe and compliant.

Scheduled inspections catch wear, corrosion, or damage before they become a risk.

Include scheduled inspections in your maintenance plan to make sure your height safety system stays compliant year-round.

- Certification and Inspections

Our height safety experts can audit your site, recommend necessary upgrades to meet the regulations, and install systems that keep your facility compliant and safe for everyone working at height.

We ensure that all installations comply with Australian safety standards, which gives you a peace of mind and a safer working environment.

Book a site appraisal or safety audit to make sure your system stays compliant and ready for use.

How Do You Choose Anchor Points?

Choosing the right anchor point depends on how and where it will be used.

Every building is different, and the best option comes down to the task, roof material, and site conditions.

Choosing the right anchorage system will keep your workers safe, compliant, and reliable for the long term.

When choosing anchor points, assess the following:

+ Application Type

Start by deciding how the anchor will be used - what would be your anchor points' purpose? Common applications and anchor point purposes include:

- Fall Arrest (15kN rated)

- Fall Restraint (12kN rated)

- Rope Access / Abseil

- Single-User vs Multi-User Systems

Each application has different load ratings and safety considerations. Understanding the intended use is essential to ensure the anchor point is fit for purpose.

+ Mounting Surface Considerations

Metal Roofs

When installing anchors on metal roofs, check the following:

- The roof sheet profile

- Purlins or truss locations

- Roof sheet thickness

- Structural strength and fixing method

Concrete Roofs and Surfaces

For concrete surfaces, assess:

- Concrete strength and thickness

- Reinforcement layout

- Age and condition of the slab

A proper site check confirms the structure can safely support the anchor and keeps the system compliant.

+ Environmental Factors

Consider how the environment affects the anchor’s lifespan.

- Exposure to rain, heat or UV

- Corrosion risks (e.g. coastal environments)

- Chemical exposure (e.g. in industrial zones)

Choosing the right materials and finishes ensures the system lasts and stays safe over time.

+ Usage Requirements

- Frequency of access

- Number of users at one time

- Type and direction of loading

- Accessibility for maintenance or inspection

These practical aspects influence not only the choice of anchor, but also its location and integration with the broader access system.

Compliance & Testing

All anchor points must meet the following Australian Standards:

- AS/NZS 1891.4:2009 – Selection, use, and maintenance

- AS/NZS 5532:2013 – Manufacturing requirements for single-point anchors

- 15kN load rating for fall arrest

- Regular inspection and testing requirements

Location Considerations

Before installation, review:

- Fall-clearance distance

- Proximity to roof edges or hazards

- Swing fall risks

- Connection to walkways or access points

Correct placement ensures the system works effectively in the event of a fall and minimises user risk.

System Integration

Anchor points should be considered as part of a complete safety solution.

Key integration needs include:

- Compatibility with static lines

- Connection to walkways and ladders

- Integration with existing or planned systems

- Flexibility for future expansion

Want to see how a practical anchor points roof access solution looks in real life on site?

Here’s an example of how Safetylyne integrated an anchor point system with static lines during a roof safety project at Brisbane’s inner-city ferry terminals.

Our height safety team provided a practical solution that solved the challenge of providing maintenance crews safe access in a busy public area.

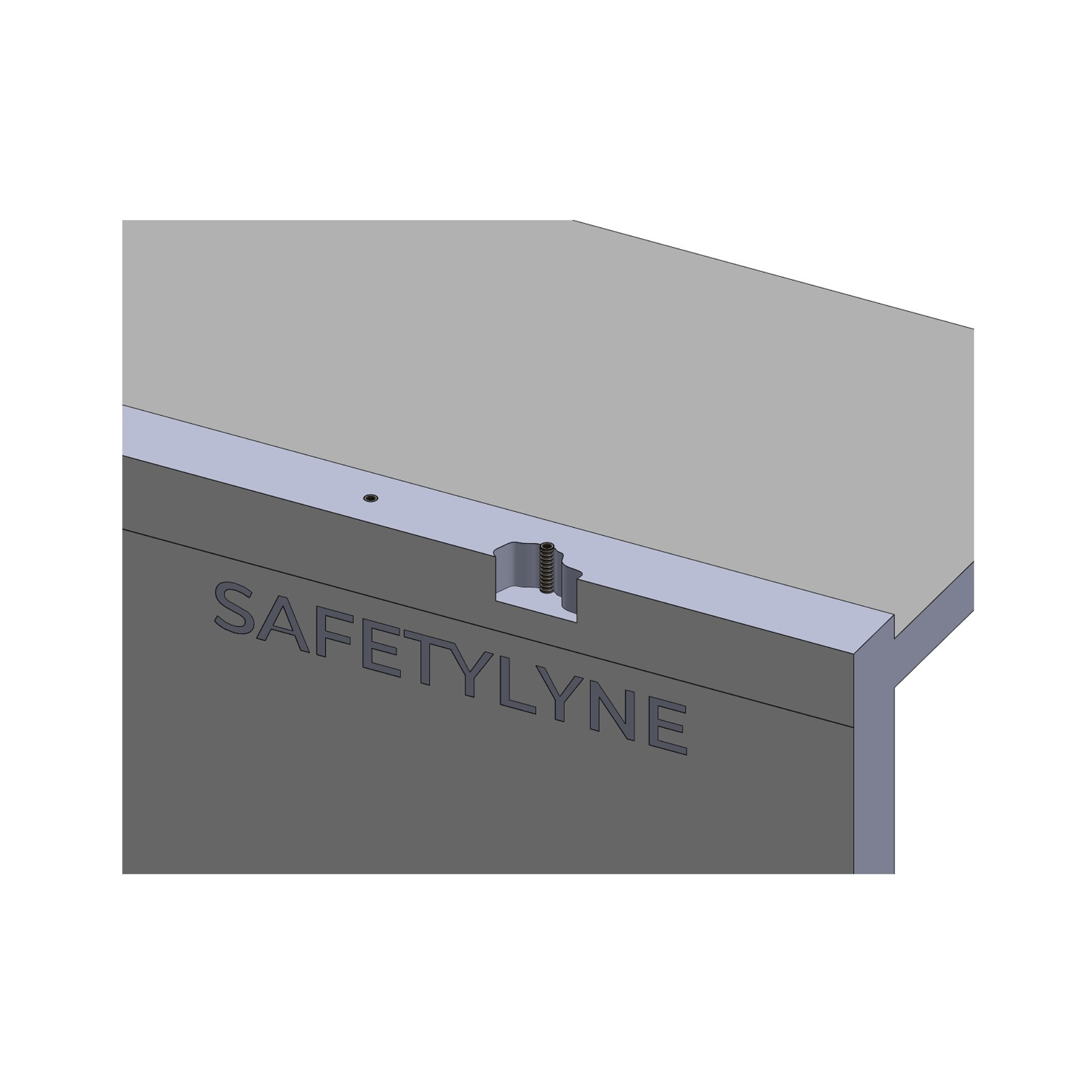

Installation & Maintenance

- Access to the installation location

- Waterproofing and sealing

- Need for structural modifications

- Ongoing inspection and maintenance access

Well-planned installation reduces risk and ensures the system performs reliably over time.

Location Considerations

Before installation, review:

- Fall-clearance distance

- Proximity to roof edges or nearby hazards

- Swing-fall risks

- Connection to walkways or other access points

- Correct placement helps the system perform properly during a fall and reduces the chance of injury.

Incorporating anchor points during the construction stage makes future maintenance safer and easier.

These systems give workers safe connection points for harnesses and fall protection gear while working at height.

Planning anchor locations early helps you build safety into the structure from the start, avoiding expensive retrofits later.

Need certified anchor point design and installation for your next project?

Contact Safetylyne for a site consultation.

Contact Our Height Safety Experts Today

Our experts are ready to provide audits, recommendations, and installations to ensure the highest level of safety for your facility.