Height SAFETY REGULATIONS Explained

Height Safety and Roof Safety Regulations in Australia

Height safety in Australia is all about protecting people who work at heights.

Roof safety measures help prevent falls and injuries during maintenance, inspections, and installations.

To manage these risks, the Australian government and industry bodies have set clear standards and rules for working at height.

Regulatory Framework

Roof safety is regulated under Australia’s Work Health and Safety (WHS) laws, which apply at both national and state levels.

- Safe Work Australia develops national policies and guidance for working at heights.

- State WHS Authorities in each region enforce those laws and manage compliance on site.

Key Standards and Guidelines

The main Australian Standards that guide roof and height safety include:

- AS/NZS 1891.4:2009 - Industrial fall-arrest systems and devices. Part 4: Selection, use, and maintenance.

- AS/NZS 5532:2013 - Manufacturing requirements for single-point anchors.

- AS/NZS 4488.1:1997 - Industrial rope access systems specifications.

- AS 1657:2018 - Fixed platforms, walkways, stairways and ladders - Design, construction and installation.

- AS/NZS 1170.1:2002 – Structural design actions.

Part 1: Permanent, imposed and other actions.

Defines the load requirements that stairs, platforms, plant decks, ladders, and access systems must be designed to withstand based on their intended use, including dead loads, live loads, and occupancy-related actions.

- Safe Work Australia Code of Practice: Practical guidance for managing height safety risks.

These standards form the foundation for safe design, installation, and maintenance of roof access systems across Australia.

See Safe Work Australia Information Sheets here.

Australian Standards for Steps, Stairs & Ladders

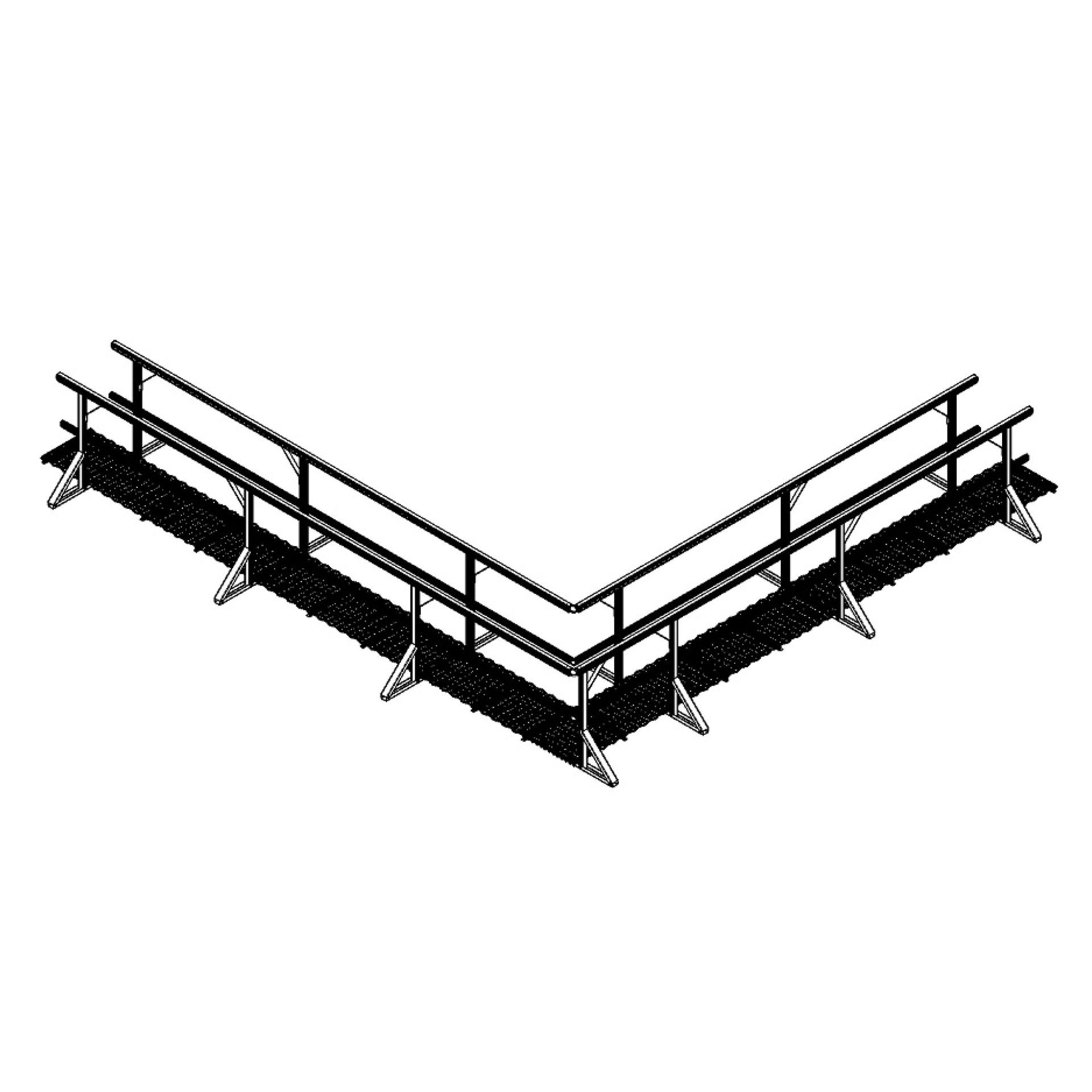

In Australia, access systems such as steps, access stairs, and access ladders must comply withAS 1657 requirements for safe design and construction.

This includes specifications for:

- Choosing the right type of access systems

- Step and riser dimensions

- Slope and angle

- Hardrail replacement

- Material and spacing dimensions

- Slope and angle of stairways

- Handrail dimensions and placement

- Clearance, landing, and access points

Meeting these standards helps reduce fall risks and ensures consistent, compliant access for workers across commercial and industrial sites.

Industry Practices

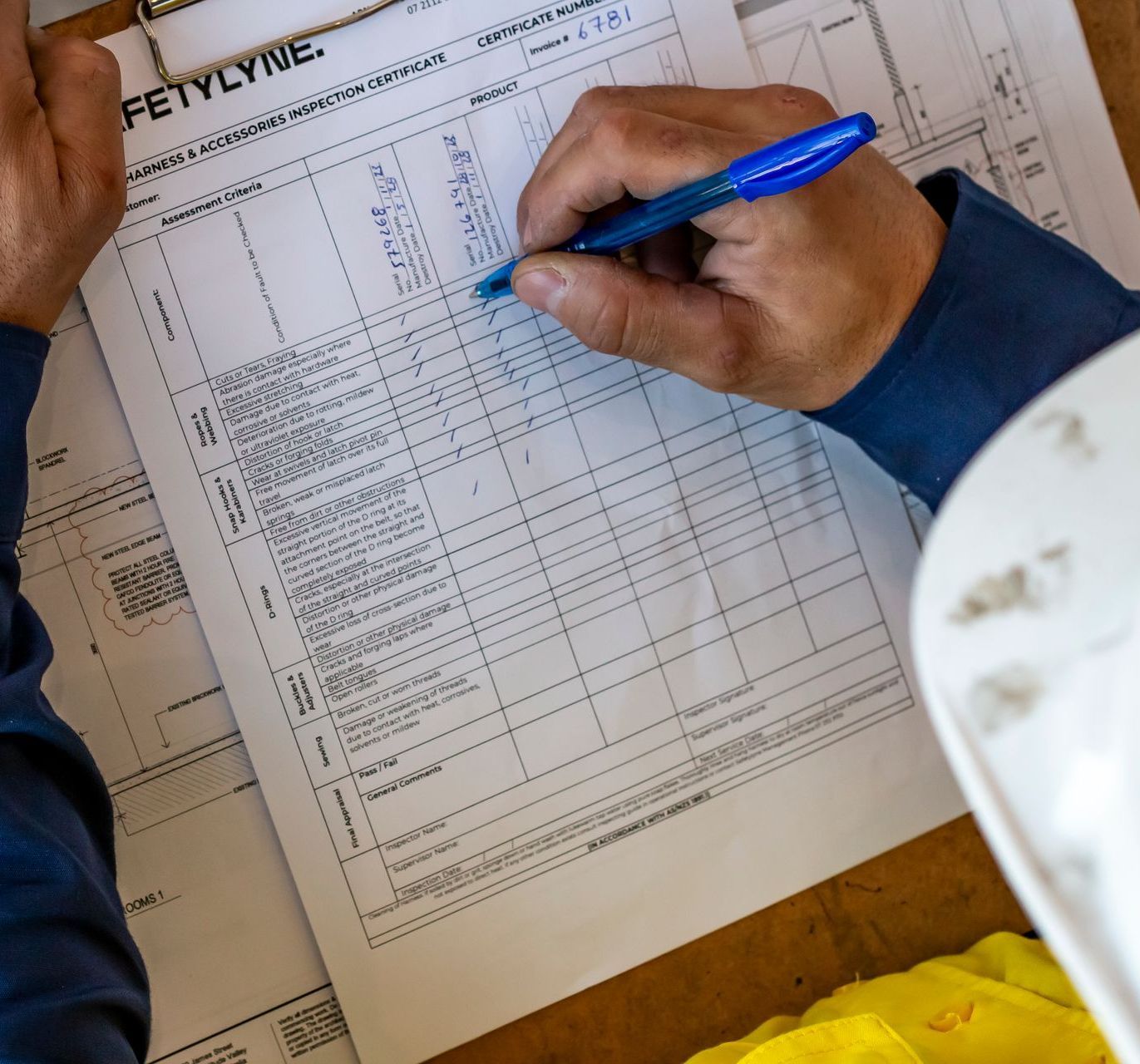

Regular inspection and maintenance keep roof safety systems effective and compliant.

Key practices include:

- Routine Inspections. Check anchor points, guardrails, and other safety equipment for damage or wear.

- Scheduled Maintenance. Repair or replace worn parts to keep systems working safely.

- Documentation. Record all inspections, maintenance, and staff training to meet WHS requirements.

Roof Safety Inspection and Recertification:

A Mandatory Requirement in Australia

Under the Work Health and Safety (WHS) regulations, roof safety systems must be inspected and recertified at regular intervals to stay compliant.

Roof safety recertification is a mandatory requirement in Australia.

Inspection frequency varies by state and territory:

- ACT, NT, QLD, SA, VIC, WA: every 6 months

- NSW: every 12 months

These inspections cover all major components, including anchor points, static lines, and guardrails.

Regular recertification confirms the system’s integrity, helps detect wear before it becomes a hazard, and keeps your site legally compliant.

Following these schedules protects workers, reduces risk, and maintains a safe, compliant workplace.

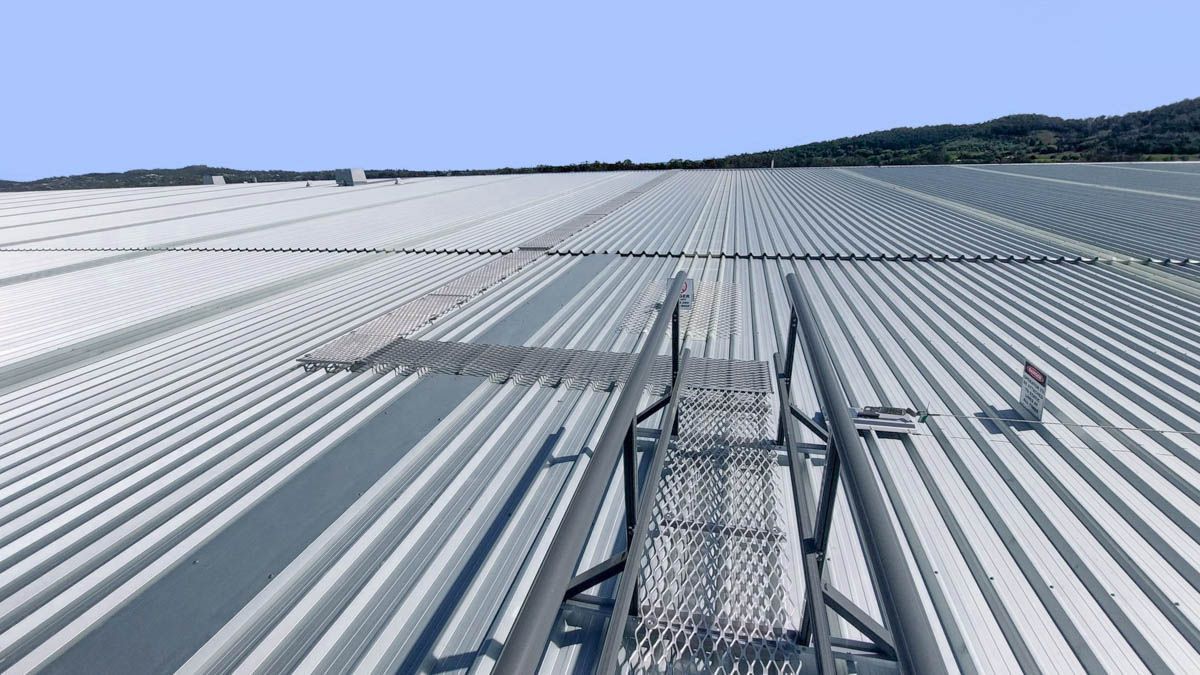

Complying with Roof Safety Regulations Without Compromising Aesthetics

A common concern when installing roof safety systems is the potential impact on a building's architectural design and aesthetic. Hence, many designers worry that roof safety systems will spoil a building’s appearance.

We believe that compliance with roof safety regulations doesn't have to come at the expense of your building's appearance.

Safetylyne designs custom systems that meet safety standards while complementing the architecture.

Our foldable guardrails stay hidden when not in use and can be raised only when needed for maintenance.

We manufacture safety systems in a range of colours, ensuring that stairs, guardrails, and platforms blend seamlessly with the building design.

Roof Platforms with integrated HVAC screens improve both safety and appearance by concealing equipment and keeping the roof area organised.

If you need compliant roof access, plant decks, or façade maintenance systems, Safetylyne can deliver a practical solution that looks as good as it performs.

Useful Resources for Height and Roof Safety

Staying up to date with height safety regulations helps you keep your workplace safe and compliant.

Here are key resources that provide official guidance and standards:

Safe Work Australia - The national body that develops model work health and safety laws, Codes of Practice, and information sheets on working at height.

State and Territory Regulators

- WorkCover QLD: WorkSafe Queensland

- SafeWork SA: SafeWork South Australia

- WorkCover NSW: SafeWork New South Wales

- WorkSafe VIC: WorkSafe Victoria

- WorkSafe WA: WorkSafe Western Australia

- WorkSafe NT: WorkSafe Northern Territory

- WorkCover TAS: WorkSafe Tasmania

- WorkSafe ACT: WorkSafe Australian Capital Territory

Safetylyne helps businesses stay compliant with Australian height safety standards through certified system design, installation, audits, and recertification.

We also provide safe access strategies, upgrades for existing systems and

recertifications.

For official regulations, visit the government regulators listed above

KEY SIGNAGE REQUIREMENTS

Wondering what signs are required for roof access under Australian regulations?

Here’s a clear summary based on

AS 1319 – Safety Signs for the Occupational Environment.

Mandatory Signs (Blue/White)

- "Safety Harness Must Be Worn"

- "Fall Protection Required Beyond This Point"

- "Attach Safety Line Here"

Warning/Hazard Signs (Yellow/Black)

- "Danger - Working at Heights"

- "Warning - Fall Hazards"

- "Caution - Fragile Roof"

- "Warning - Limited Weight Capacity"

Restricted Access Signs (Red/White)

- "Authorised Personnel Only"

- "No Access Without Permit"

- "Restricted Area - Height Safety Equipment Required"

Information Signs (Green/White)

- "Emergency Assembly Point"

- "First Aid Station"

- "Emergency Contact Numbers"

Location Signs

- "Anchor Point Rated for X kN"

- "Static Line System"

- "Access Point"

General Requirements For Safety Signs

- Signs must be clearly visible and placed at all access points.

- Maintain signs in good condition and ensure they meet AS 1319 colour codes.

- Include load ratings and emergency contact information where relevant.

Differences Between NSW and QLD Height Safety Regulations

Height safety rules in Australia follow the same WHS framework, but some details vary between states.

Understanding the specific height safety regulations in New South Wales (NSW) and Queensland (QLD) is crucial for ensuring compliance and safety in construction and other high-risk industries.

Here’s how New South Wales (NSW) and Queensland (QLD) differ.

NSW Height Safety Regulations

- General Requirements

Part 4.4 of the WHS Regulation 2017 covers fall risks in elevated workplaces, including edges, openings, and fragile roofs. - Hierarchy of Controls

NSW enforces a strict hierarchy: remove the hazard first, then use fall prevention measures such as guardrails or restraint systems, followed by fall arrest as a last resort. - Safe Work Method Statements (SWMS)

A SWMS is required for any construction work where the fall risk is greater than two metres. It outlines the control measures and safety steps to follow during the job.

QLD Height Safety Regulations

- Height Thresholds

Fall prevention is mandatory at heights of three metres or more, or two metres in general construction. - Control Measures

QLD height safety regulations focus on strong fall prevention controls such as guardrails and edge protection. If these aren’t possible, fall arrest systems must be used. - Detailed Guidance

Queensland provides more specific details on systems like edge protection, travel restraint, safety nets, and harness-based fall arrest setups.

Both states follow national WHS laws, but Queensland generally includes more detailed and prescriptive requirements for fall prevention systems.

Other States

Requirements for

Height safety inspections in South Australia differ slightly - safety systems must be checked every six months, compared to 12 months in NSW.

These differences highlight the importance of checking local regulations to keep your site safe and compliant.

For a full overview, see our guide on [Roof Safety Regulations: Australia vs the Rest of the World].

Learn everything you need to know about SA roof safety here.

For insights into how Australia’s roof safety regulations compare to those in the US and Europe, check out our blog: Roof Safety Regulations: Australia vs. the Rest of the World.

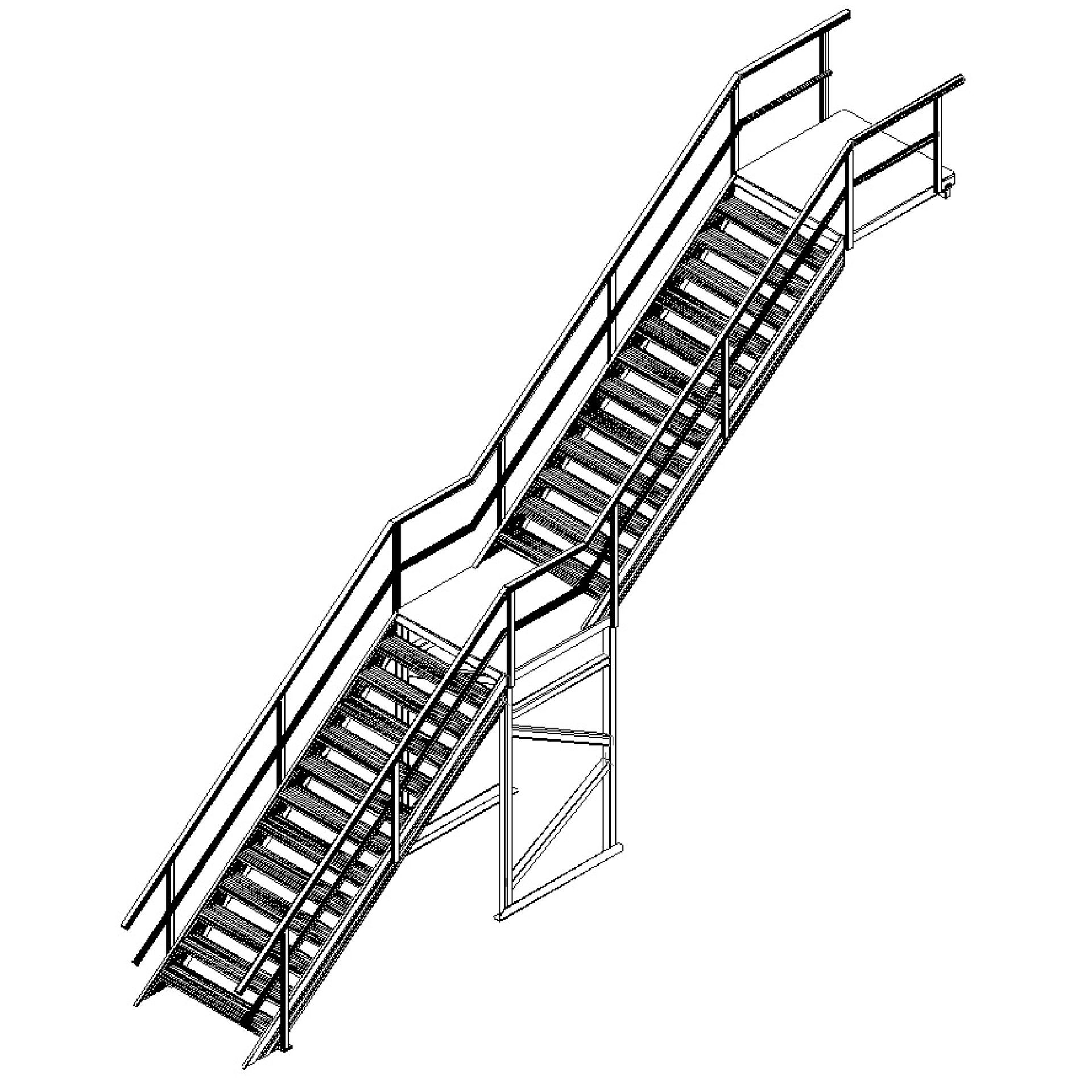

Fire Escape Stairs: Essential for Emergency Egress Compliance

Fire escape stairs allow safe evacuation during an emergency and are essential for multi-storey buildings.

Under the

National Construction Code (NCC), any building higher than 25 metres must have at least two fire-isolated exits, usually including fire escape stairs.

These stairs must

comply with AS 1657:2018, which covers fixed platforms, walkways, stairways, and ladders.

- Minimum clear width - at least 1 metre, depending on building type and occupancy.

- Non-combustible construction - Typically steel or aluminium.

- Slip-resistant surfaces - to prevent slipping in wet or emergency conditions.

- Consistent rise and going - compliance with AS 1657:2018 to ensure safe and predictable movement.

- Handrails and edge protection - continuous handrails, midrails, and kickplates where required.

- Unobstructed access - stairs must stay clear, well-marked, and accessible at all times.

Installing compliant fire escape stairs not only meets NCC requirements but also improves safety for everyone using the building.

For more details on Safetylyne’s compliant stair systems, visit our Fire Escape Stairs page.

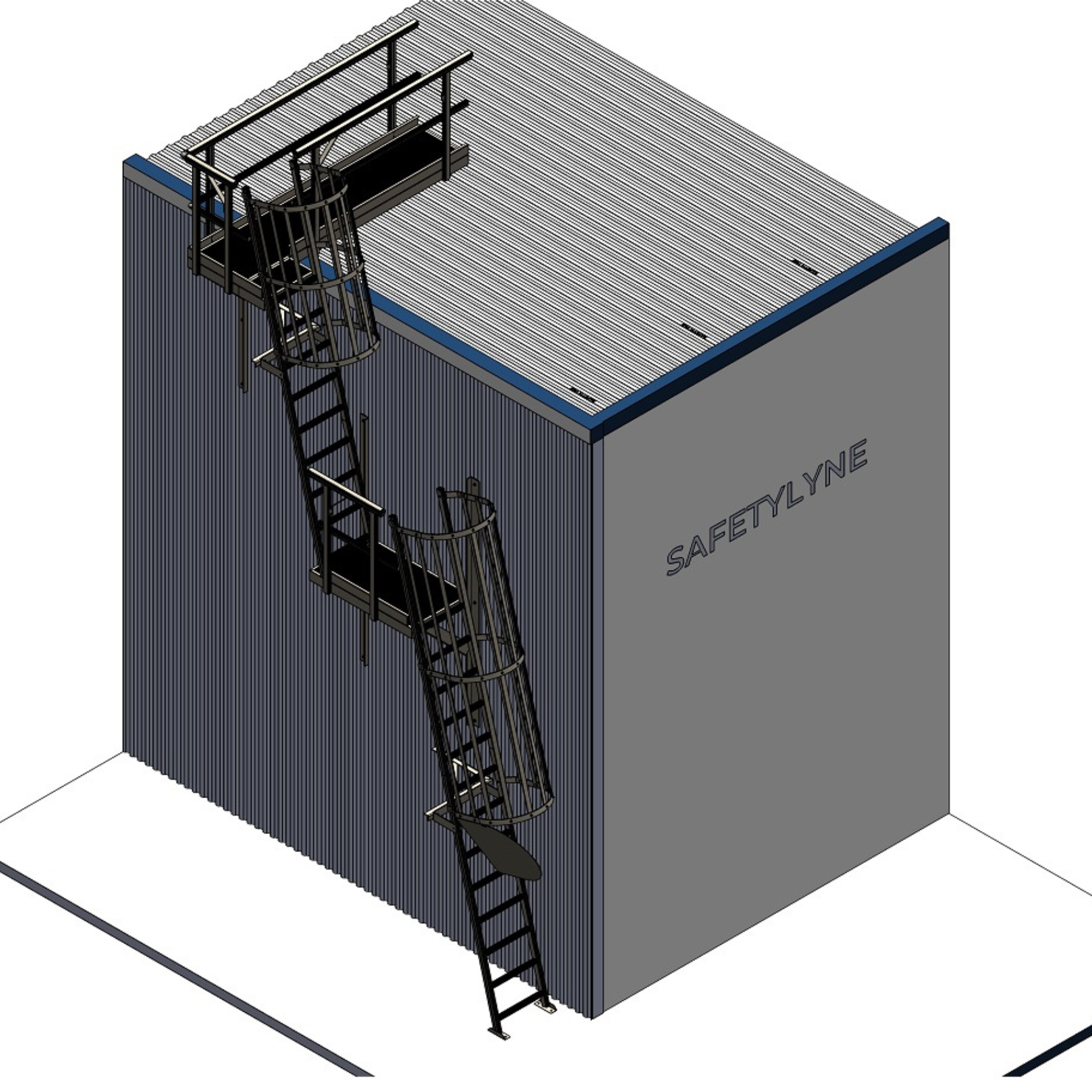

Safetylyne Way

With more than 25 years of industry experience, Safetylyne designs and installs complete roof and height safety systems across Australia.

Our work covers everything from design, engineering, and fabrication to installation and certification.

All Safetylyne systems are NATA-certified and fully engineered to meet Australian standards.

We specialise in custom fall prevention and access solutions, including static lines, anchor points, platforms, stairs, gantries, and rail systems , built for various industries and applications - construction, food processing facilities, HVAC, horticulture, mining height safety and access, and solar maintenance.

Each system is tailored for long-term performance, safety, and compliance in demanding environments.

Talk to HEIGHT Safety Experts

Let's discuss your project