Understanding

AS1657

AS1657 is the Backbone in Safe Access Design and everything we do in height safety.

AS 1657 : 2018 is the Australian Standard governing the design, construction, and installation of

fixed platforms,

walkways,

stairways, and

access ladders. It serves as the benchmark for ensuring safe access in industrial and commercial settings, aligning with

the hierarchy of controls and the Code of Practice for managing the risk of falls at workplaces.

It ensures every access point and elevated area is designed to minimise fall risks and support safe movement.

AS 1657 code applies to:

- Roof access systems and plant decks

- Service walkways and maintenance platforms

- Fixed ladders, stairs, and guardrail systems

- Access to tanks, silos, and elevated structures

In short, if someone needs to reach, maintain, or inspect equipment at height, AS 1657 guides you on how to make that access safe.

Key Requirements Explained

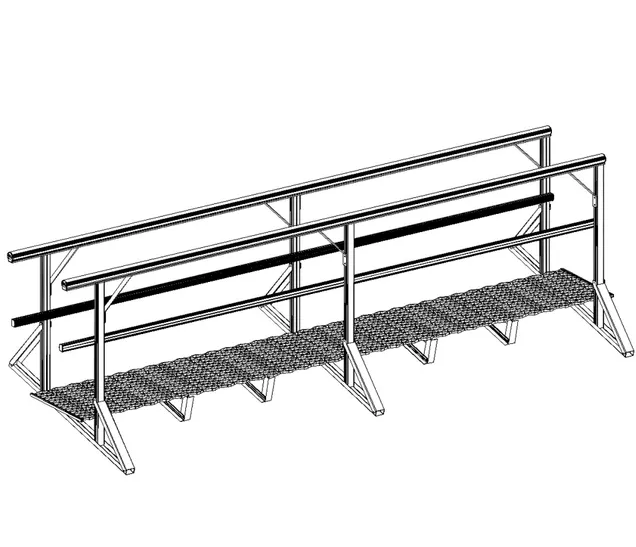

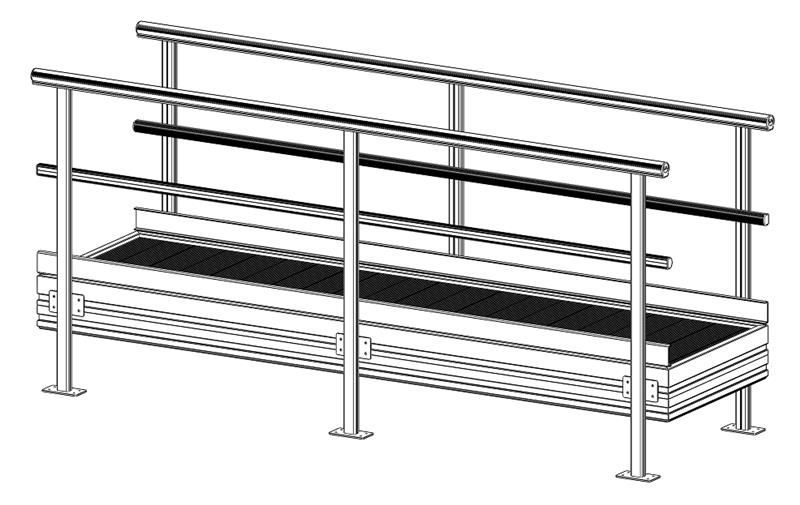

1. Walkways and Platforms

Walkways can slope up to

20°, with specific cleat spacing and slip-resistant surfaces required when the slope exceeds 7°.

Guardrails and toeboards are mandatory wherever there’s a drop of 2m or more to prevent objects or people from falling.

2. Guardrails and Toeboards

Guardrails must be between

900 mm and 1100 mm high, with rails spaced no more than

450 mm apart, and toeboards at least

100 mm high.

All systems must withstand a load of 550 N applied horizontally or vertically to the top rail.

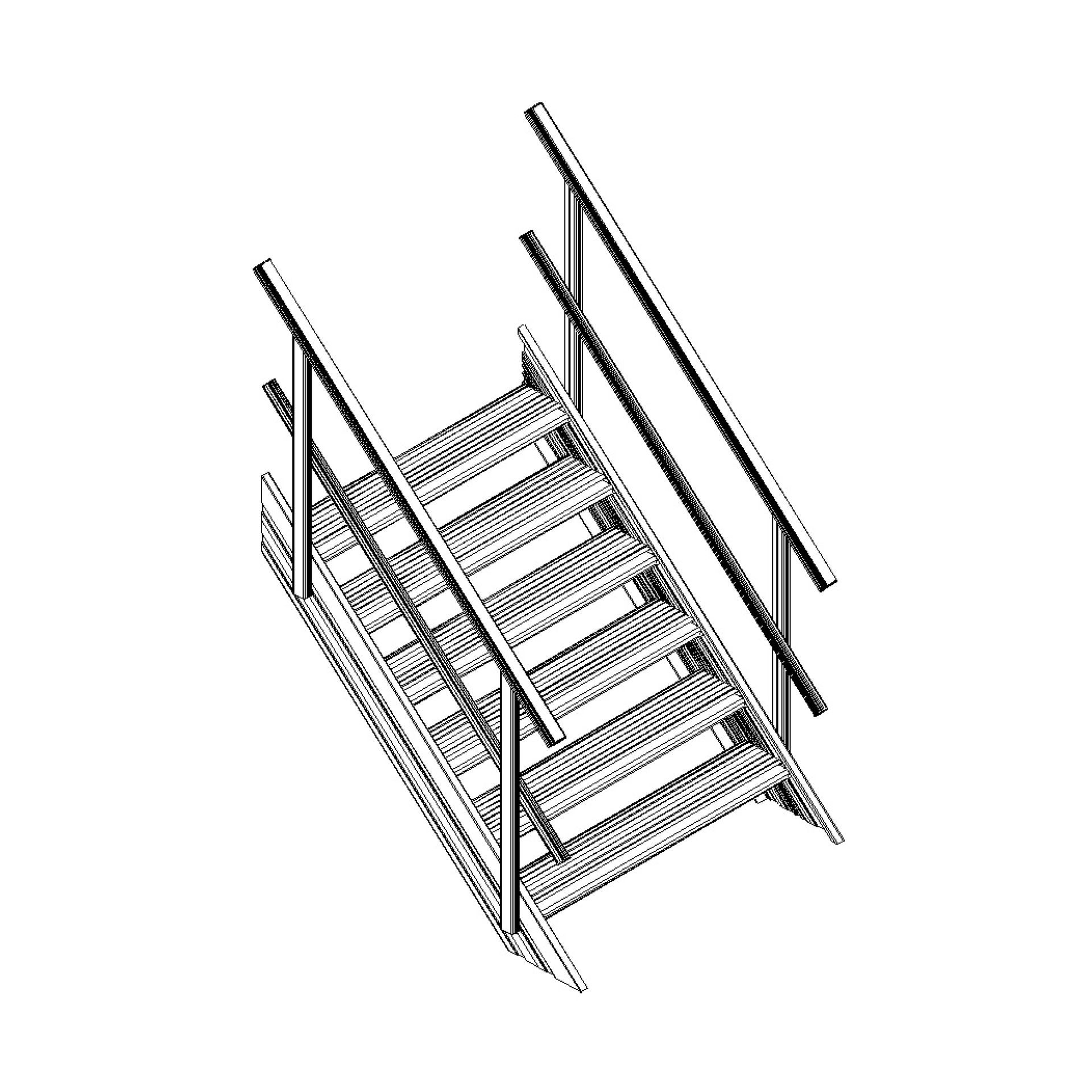

3. Stairways

- Slope: 26.5°–45°

- Width: Minimum 600 mm between handrails

- Rise and Going: 150–215 mm rise, 215–305 mm going, uniform across the flight

- Landings: Required every 18 risers (about 3.6–4 m vertical rise)

- Handrails: Required on at least one side, or both if the stair exceeds 1,000 mm width.

4. Fixed Ladders

- Vertical ladders up to 90° require cages or fall protection when over 6m in height.

- Rest platforms are required every 6 m of vertical climb.

- Clearance behind rungs: Minimum 200 mm from the wall.

- Rung spacing: 250–300 mm.

- Minimum width: 375–525 mm between stiles.

5. Step Ladders and Maintenance Access

Inclined ladders (60°–70°) used for service or restricted areas fall under AS1657 when used for roof or plant access, rather than general public access.

These can have open risers and a narrower width (min. 600 mm), given they’re only used by trained personnel.

The Hierarchy of Safe Access (AS1657 + WHS Guidance)

AS1657 ranks access systems by safety and usability - from lowest to highest risk:

- Walkways and Platforms (0–20°) – safest and most stable.

- Stairs (20–45°) – safe for regular access and movement of tools.

- Inclined Step Ladders (60–70°) – suitable for infrequent access.

- Inclined Rung Ladders (70–75°) – higher risk, for maintenance access only.

- Vertical Ladders (90°) – highest fall risk, only for restricted access with cage or fall arrest system.

This hierarchy is embedded into Safetylyne’s design process to ensure systems are always engineered for the lowest practicable risk level.

Why Following AS1657 Makes a Real Difference For Your Workplace Safety

AS1657 isn’t a legal requirement on its own - it’s a technical safety standard that guides how to design and install compliant access systems and roof access.

However, it’s widely recognised by regulators and inspectors as the benchmark for best practice in fall prevention and workplace safety.

Access Systems designed and installed to AS1657 standard help maintain compliance with WHS obligations, reduce overall project risk, and improve your site safety.

In practice, adhering to AS1657 means:

- Lower safety risk: Minimises the chance of falls, slips, and injuries during routine maintenance or inspections.

- Documented compliance: Provides engineering assurance that every platform, walkway, or ladder meets load, spacing, and clearance requirements.

- Easier certification: Simplifies audits and future safety recertification processes.

- Project confidence: Reduces the likelihood of redesigns, delays, or liability issues if the system is ever reviewed by a safety authority.

Where the AS1657 standard can be used as guidance for your height safety

You can find AS1657 applied in many environments, for example:

- Roof access, plant decks, and plant rooms

- Tanks and silos access

- Marine and offshore structures access solutions

- Airports and hangars height safety

- Warehouses and manufacturing facilities access

What Changed in the 2018 Revision of AS:1657

The 2018 update refined several key definitions and design clauses:

- Clearer requirements for ladder cages, rest platforms, and handrails.

- Enhanced focus on fall protection, including when safety lines or cages are required.

- Updated figures and tables to remove ambiguity around landings, riser heights, and loading performance.

- Stronger alignment with risk hierarchy principles, prioritising walkways and stairs over ladders where possible.

+ Integration with Safetylyne Access Solutions

At Safetylyne, AS 1657 is not just a guideline - it is the backbone for designing and engineering of our access solutions.

For detailed information on AS1657, refer to the official documentation provided by Standards Australia.

To learn more about

roof safety systems design and applications here.