Warehouse and Distribution Centres Height Safety Systems

How to identify risks, choose the right ACCESS systems,

and meet compliance obligations in warehouse and distribution centre environments.

Warehouses and Customer Fulfilment Centres aren’t built for standing still. They’re high-volume, high-movement environments - generally designed for throughput, not for fall protection.

But working at height happens everywhere:

on roofs, mezzanines, racking, service platforms, conveyors, loading docks access zones and docking stairs, machinery maintenance areas, maintenance works inside ceiling spaces, etc.

This warehouse access systems guide outlines the critical safety risks, relevant Australian legislation, and the practical steps facility managers, safety leads, and asset owners can take to create safer, more compliant warehouse operations.

1. Height Risks in Warehouses and CFC

Height risks are embedded in everyday tasks in distribution centres. Some are obvious, and some are easy to miss in the planning stages.

Here are some common height safety-related activities that have to be considered for warehouse safety management:

- Accessing elevated storage or stock locations

Maintenance teams in most warehouse and manufacturing facilities use ladders, platforms or hire scaffolds or elevated work platforms to conduct maintenance or emergency work above head height.

Without the right systems in place (like compliant step platforms, guardrails or fall restraint / arrest lines or rails), these everyday tasks can pose serious risks.

- Safe access to overhead, enclosed conveyor or racking systems

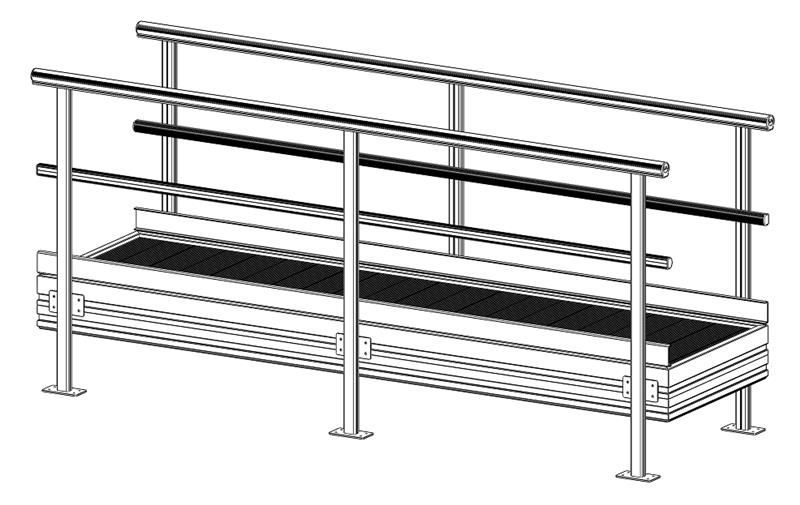

Maintenance, repairs, or cleaning processes often require workers to operate at height or near edges, especially where conveyors or processing plants are suspended or at multiple levels. Fixed walkways, platforms, and fall protection systems are essential to ensure safe and efficient access.

- Loading dock and truck access

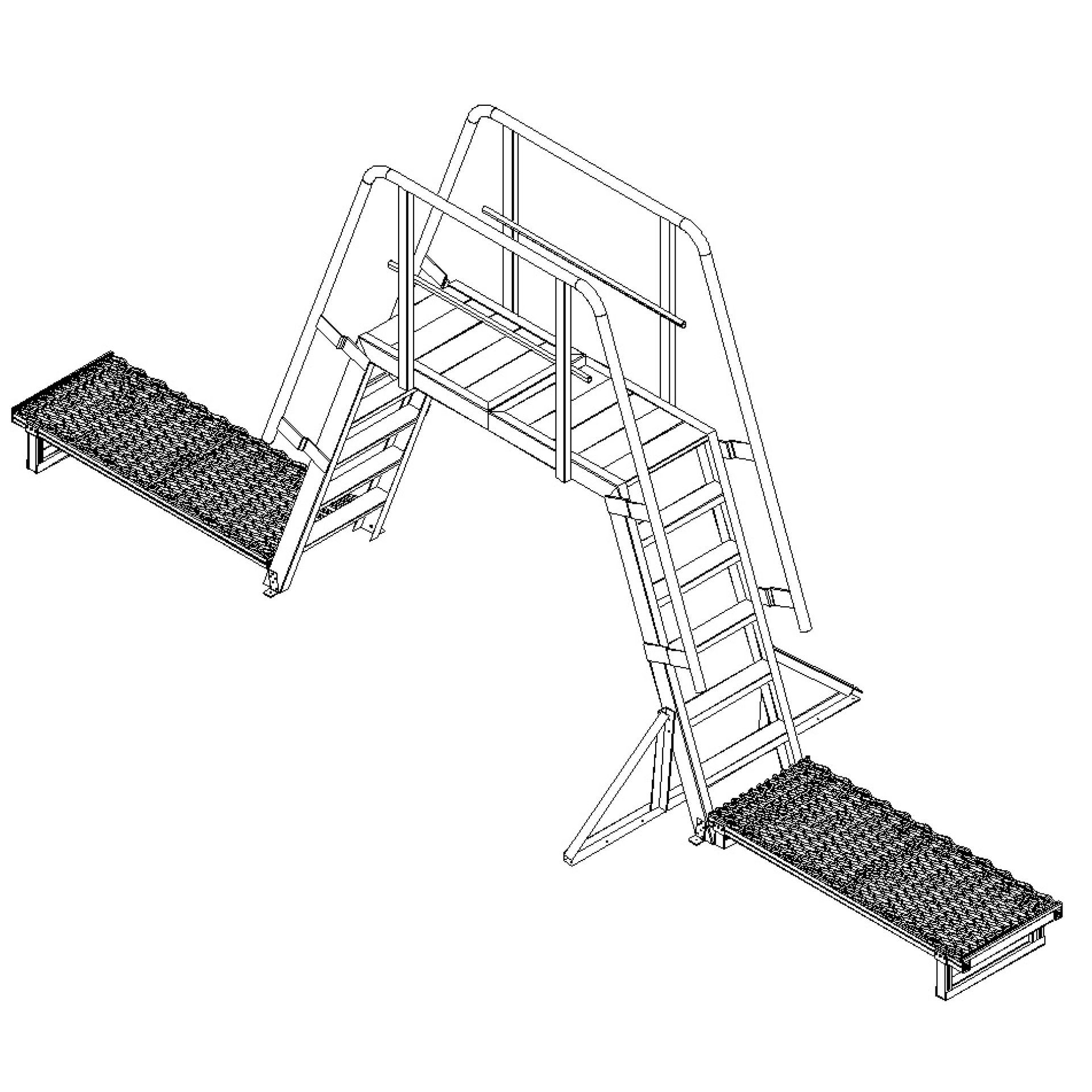

Workers often need to access the tops of trucks or containers for loading, unloading, cleaning and maintenance, or securing cargo. This requires compliant edge protection or mobile access platforms to prevent falls by engineering out the risk.

- Accessing elevated storage or stock locations

In many cold storage facilities, staff need to use ladders or platforms to retrieve or store misplaced stock above head height. Without the right systems in place (like compliant step platforms, guardrails or fall restraint/ arrest lines/rails), these everyday tasks can expose workers to serious fall risks.

- Accessing rooftop HVAC, solar systems, plant machinery and cooling towers

- Replacing high bay lighting or ventilation fans

- Servicing racking, conveyors, or gantries

- Performing inspections and compliance checks on the plant

- Emergency or ad hoc access by maintenance contractors

2. Understanding Your Legal Obligations For Warehouse Management

Work Health and Safety (WHS) Legislation

Under Australia’s WHS Act and Regulations, employers and PCBUs (Persons Conducting a Business or Undertaking) must eliminate or minimise the risk of falls from one level to another, as far as reasonably practicable.

This includes providing:

- Safe access to areas where work is carried out

- Engineering access systems to prevent falls (e.g. guardrails, walkways)

- Personal fall protection (PPE is the least preferred control measure)

- Maintenance and inspection of all safety systems

Failure to manage these risks can potentially result in prosecution - even if no incident occurs.

3. Key Australian Standards for Warehouse Access and Fall Protection

Warehouse systems will need to comply with the following core standards:

Standard & What It Covers

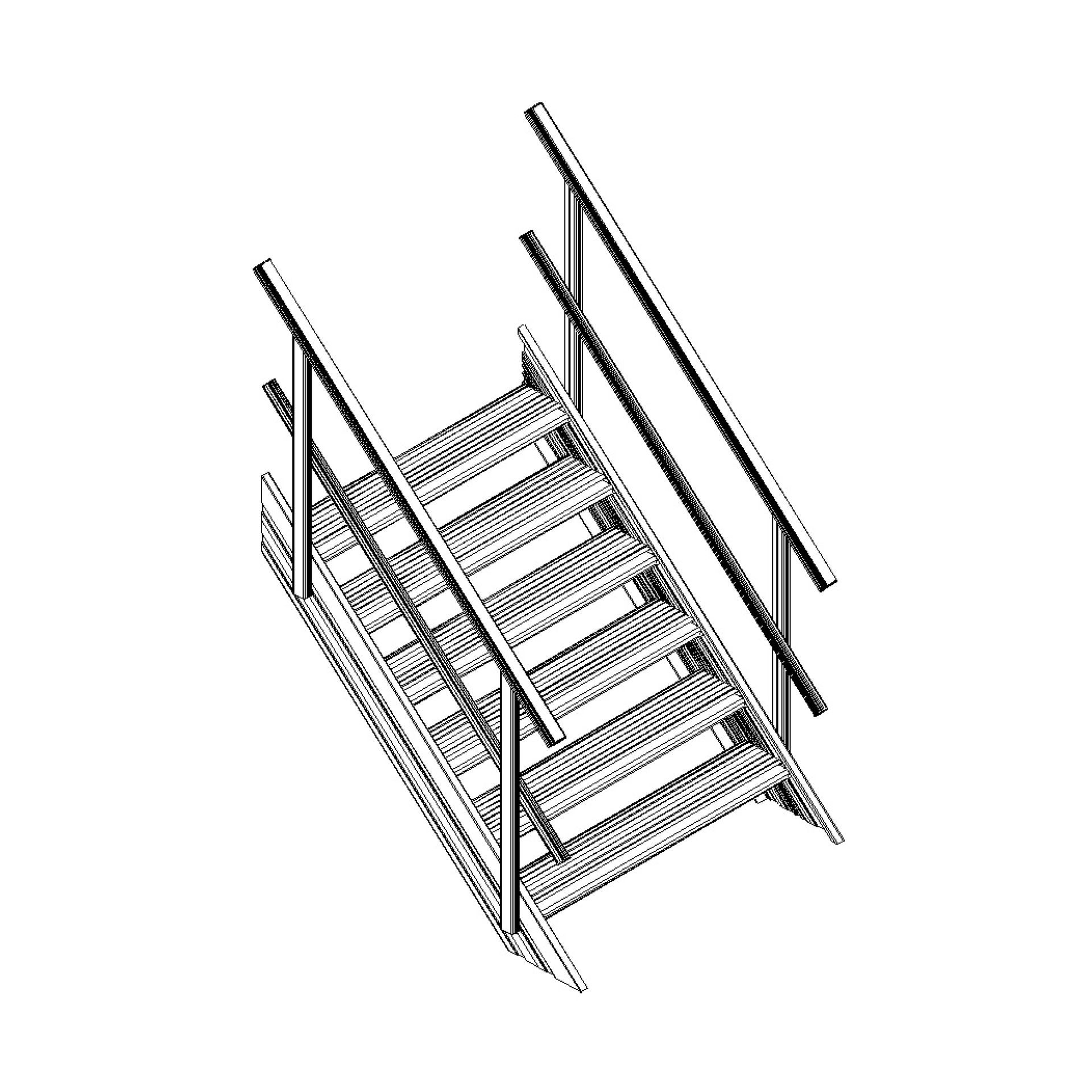

AS 1657:2018 - Fixed ladders, stairways, walkways, and guardrails

AS/NZS 5532:2013 - Single-point anchors for harness-based systems

AS/NZS 1891 series - Fall arrest systems and equipment compatibility

Code of Practice, Managing the Risk of Falls - How to apply the hierarchy of control (Safe Work Australia)

It is not enough to install compliant components - the entire system will need to be designed, installed, certified, and supported with appropriate system induction training.

4. The Hierarchy of Control: What Compliance Looks Like in Practice

Compliance isn't just having PPE on site. It means designing your environment to eliminate or reduce the need to work at height, and ensuring that any remaining access is protected.

From most to least effective:

- Eliminate the need to access height (e.g. relocate plant to ground level)

- Use fall prevention systems (e.g. guardrails, walkways, stairs)

- Use fall restraint systems with arrest capability (e.g. anchor points + harness, static lines)

- Use administrative controls (e.g. procedures, permits, supervision)

- Use PPE as a last resort

Warehouses often require a mix of engineered controls - walkways, rails, ladders, platforms - complemented with a personal protection system where required.

6. Design Considerations for Warehouse Height Safety

When planning warehouse access and protection systems:

- Engage early: Late-stage retrofits are more expensive and can be more complex

- Map out the frequency of access for maintenance and inspection tasks required for access areas.

- Design for usability, considering the practical application of systems - systems that are too hard to use have the tendency to be bypassed

- Consider multiple trades: Electrical, HVAC, fire, pest control, potential emergency service access and maintenance teams - who may access the area

- Allow for future servicing: System longevity depends on accessibility and re-certification maintenance

Good safety design addresses not only risk management, but also balances functionality, durability, and operational flow.

7. Inspection, Maintenance & Record-Keeping

Compliance doesn’t end at building access system's installation. Systems must be:

- Inspected regularly – e.g. anchors every 12 months per AS/NZS 1891

- Records are maintained according to the original design specification

- Recertified on schedule, with records stored and accessible

- Supported by training for anyone authorised to use fall restraint/ fall arrest systems

A system without documentation or inspection history is not compliant, regardless of how it looks.

8. Key Questions for Warehouse Operators & Safety Representatives

- Have all access and servicing tasks at height been identified and risk assessed?

- Do all elevated areas have appropriate fall prevention or arrest systems?

- Are those safety systems compliant, certified, and documented?

- Who is responsible for the access system inspection and

re-certification?

- Are external contractors using the system correctly and safely?

- Do they achieve the residual risk outcomes required by your company?

How To Meet Warehouse Compliance Access with Fire Escape Stairs?

Multi-level warehouses or mezzanine structures may require fire escape stairs as a key compliance requirement under the NCC.

They provide essential emergency access egress and must integrate with other access systems to ensure safe and uninterrupted evacuation from elevated areas.

Where stairs intersect with roof access or height safety zones, access systems should be configured together to meet both fall protection and egress standards. Considerations to be given to the behaviours of the building elements, clearances and structural integrity.

Summary: Height Safety is a System, Not Just a Product

Compliance is not just a regulatory checkbox. It’s a framework for protecting lives, ensuring continuity, and reducing liability in environments where working at height is often necessary but easily overlooked.

Warehouse fall risks can’t be solved with a single anchor or a policy.

They are a system that requires integrated, engineered solutions designed for real-world conditions and maintained over time.

What Sets Safetylyne Apart

+ Warehouse-specific expertise – We understand the spatial, operational, and safety complexities of warehouse environments, and we have completed multiple warehouse projects, where these needs have been a high priority.

+

End-to-end delivery

– No subcontracting, no patchwork systems, no design gaps. We design, engineer, and fabricate access systems in-house to suit your unique application, to enable quality control and delivery of the correct solution.

+

Lifecycle support

– Design, certification, inspection, and recertification all under one roof. Up to 25 years warranty on access systems (subject to regular inspections).

+ Architectural coordination

– We ensure systems integrate cleanly with building design, services, and movement flows.

+ Premium execution – Safetylyne is focused on providing world-class delivery experience and is trusted by government entities, airlines, tier 1 builders, architects, and engineers.

Need Warehouse Height Safety Solutions That Work?

Whether you're operating an existing warehouse or building a new facility, Safetylyne delivers height access and fall protection solutions that keep your people safe - and your compliance requirements in order.

Access solved.

Get in touch to discuss your warehouse safety requirements.

CONTACT OUR TEAM

Contact Us

WAREHOUSE HEIGHT SAFETY SYSTEMS CASE STUDIES

Completed projects IN SITU