Roof Hatches & Ceiling Access

Safe roof access is key for regular maintenance, inspection, and compliance of your building.

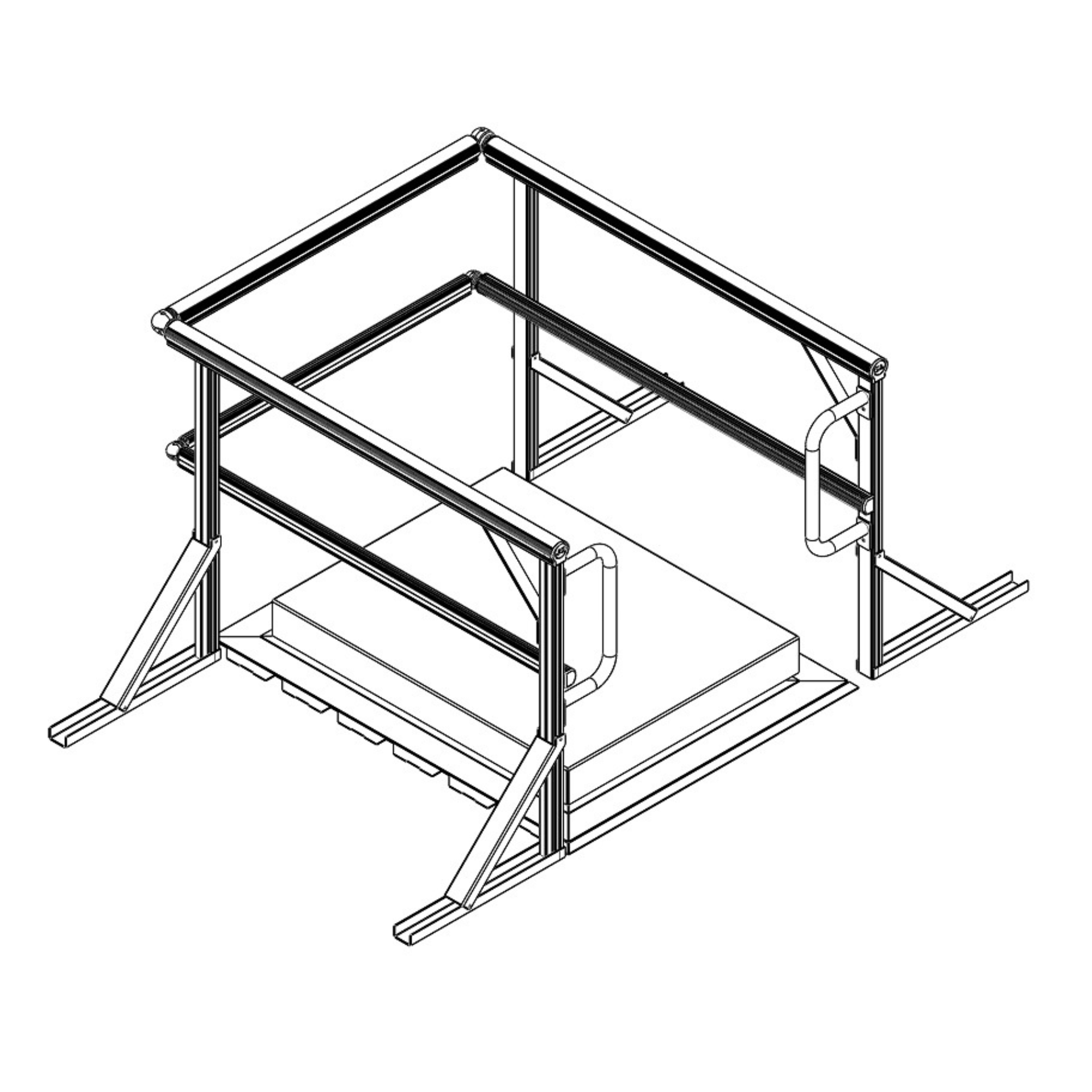

Safetylyne designs and installs roof access hatches, fold-down ladders, and ceiling void ladders that allow controlled, secure entry through internal spaces to roof areas for maintenance access purposes.

We manufacture both proprietary and custom-engineered hatch systems to match each site’s layout, building design, and operational needs.

Roof access hatches create a safe and simple authorised entry point to the roof for maintenance, inspection, or emergency use.

Roof hatch enhances safety providing a controlled and secure roof and ceiling access method. It reduces risk of falls and accidents. The hatch can be locked and keyed to match your site’s existing access control system.

Metal roof hatches are essential in commercial, industrial, and residential buildings where workers need controlled internal access to roof areas.

What You Need to Know About Horizontal Access Hatch

How Roof And Ceiling Access Hatches Work?

Design and Structure

- Safety roof hatches are built from powder-coated aluminium for strength and weather resistance for long service life.

- Standard colour with bespoke colour options available on request to suit your site design, colour coordination and aesthetics.

- Each hatch includes a fully welded frame with corrosion-resistant hinges for smooth operation and durability.

- Insulated covers reduce heat loss, while integrated weather seals prevent water and dust, maintaining high performance in all conditions.

Hatch Access Mechanism

Roof hatches can be open manually or with the support of gas struts or torsion bars that make lifting and closing smooth and controlled.

Some hatch models include locking systems to prevent unauthorised entry, while others are built with sliding panels that move horizontally to save space and improve usability,

and optimise space inside the ceiling cavity.

Safety Features

Each hatch is designed for safe use, with features such as non-slip surfaces, secure handholds, and

integrated ladders that help users move safely between levels.

These elements reduce fall risk and make maintenance or inspection access simple and controlled.

Many roof hatches are designed with integrated safety features such as non-slip surfaces, handrails, and ladder systems to ensure safe ascent and descent for users.

Types of Roof Hatches

+ Standard Roof Hatches

Basic models designed for general access. Reliable, everyday models for routine access and maintenance.

+ Security Roof Hatches

Enhanced security features to prevent unauthorised access.

+ Sliding Hatches

Use a horizontal sliding lid design for compact spaces where a hinged hatch cannot fully open.

Do you actually need a roof hatch?

Benefits of having a roof hatch in your building or facility

+ Safety

Provides a secure and controlled access point, reducing the risk of falls and accidents.

+ Convenience

Allows easy access for maintenance and inspection tasks, saving time and effort.

+ Energy Efficiency

Insulated designs help maintain building energy efficiency.

+ Versatility

Available in standard sizes and configurations to suit different building requirements, with the ability to build custom hatches to address site needs.

+ Aesthetic Architecture Design Considerations

For buildings where aesthetic considerations are important, custom hatches can be designed to blend seamlessly with the architectural style and appearance of the structure.

+ Space Constraints

In situations where space is limited, custom access hatches can be designed to maximise available space and ensure safe, efficient access.

+ Compliance with Specific Standards

Some construction projects require compliance with unique safety or building / facility standards that regular hatches do not meet.

Custom hatches can be designed to adhere to the specific regulations and site layout requirements.

Incorporating Additional Features

When there is a need for additional features like skylights, ventilation, or fire-rated capabilities, custom hatches can be designed to integrate these elements seamlessly.

Roof Hatches Installation and Maintenance

+ Professional Installation

It's recommended to have your access systems installed by professionals to ensure they meet safety and building codes.

+ Regular Inspections

Periodic inspections and maintenance are necessary to ensure the hatch remains functional and secure.

+ Compliance

Ensure that the roof hatch complies with relevant safety standards and regulations.

+ Water tightness

A flashing system to be installed to achieve water tightness and storm water control around the roof hatch penetration.

How to Choose the Right Roof Hatch

+ Material

We recommend choosing aluminum for the higher durability and longevity of your roof access systems.

+ Size and Configuration

Bespoke designs available upon request. Select the appropriate size and design to meet your specific access needs.

+ Safety Features

Consider additional safety features like handrails and guardrails, non-slip surfaces and roof walkways for enhanced safety.

Does Your Roof Hatch Need a Guardrail?

Installing guardrails around roof hatches is an important consideration in roof safety. Here are some factors to help determine if your roof hatch needs a guardrail.

Safety Regulations

Many safety standards and regulations, including AS/NZS 1891.4:2009 and AS/NZS 1657, recommend or require the installation of guardrails around roof hatches to prevent falls and ensure the safety of workers.

Australian Safety Regulations for Roof Access Hatches

In Australia, the design, installation, and use of roof hatches are governed by strict safety regulations to ensure that workers and personnel can access roof areas safely, particularly in commercial and industrial settings.

The primary focus of these regulations is to prevent falls and other accidents associated with working at heights.

1. Compliance with AS/NZS 1657:2018

Roof hatches must meet the

requirements of

AS/NZS 1657:2018, the Australian Standard that defines safe design and construction for fixed platforms, walkways, stairways, and ladders.

The standard sets out how roof access hatches should be built and installed to ensure safe entry and exit for maintenance or inspection work. Ladder configurations and clearances around the roof hatch opening need to be a high priority to meet the requirements of AS/NZS 1657:2018.

It specifies the materials, load strength, and essential safety features such as guardrails, secure locks, and slip-resistant surfaces, helping prevent falls and injuries during use.

2. Fall Protection Requirements

Under the Work Health and Safety (WHS) Regulations, roof hatches are required to include fall protection measures.

This may include the integration of guardrails, safety harness attachment points, and self-closing mechanisms to prevent accidental falls and provide suitable control measures for risk reduction.

The height safety equipment must also be regularly inspected and maintained to remain compliant.

3. Safe Work Australia Guidelines

Safe Work Australia provides additional guidelines and codes of practice that influence how roof hatches are utilised on-site.

Safe Work Australia outlines clear guidelines for using roof hatches safely on site.

These include completing a risk assessment before accessing a roof, ensuring workers are trained in height safety, and using roof hatches designed for controlled, easy access.

Employers must confirm that every installed roof hatch meets Australian safety standards and is maintained to prevent any risk to workers.

4. Building Code of Australia (BCA) Compliance

Roof hatches must also comply with the Building Code of Australia (BCA), which mandates specific construction and safety standards for building components.

The BCA covers aspects like fire safety, structural integrity, and weatherproofing, all of which impact the design and installation of roof hatches.

5. Maintenance and Inspection Requirements

Regular inspection and maintenance of roof hatches are mandatory under Australian regulations.

This includes checking for signs of wear and tear, ensuring that locking mechanisms and safety features are functional, and verifying that the hatch remains secure and compliant with all relevant standards.

Adhering to these regulations is crucial for ensuring the safety of workers accessing roof areas through hatches. Compliance with AS/NZS 1657:2018, WHS regulations, and the BCA ensures that roof hatches are safe, reliable, and fit for purpose.

Regular maintenance and risk assessments further enhance safety, helping to mitigate the risks associated with working at heights.

For more detailed information, it's advisable to consult with a professional in height safety or refer directly to the relevant Australian standards and regulations.

Roof hatches can be positioned to provide safe internal access between different levels within a facility.

In environments such as cold storage and manufacturing facilities, they connect floors or compartments, allowing personnel to move safely using internal stairs or access ladders and providing

safe access for work inside ceiling cavities.

This approach works well where space is limited and conventional stairways are not practically suitable for the adjacent building elements.

It keeps movement between levels secure, efficient, and fully compliant with safety standards.

Safetylyne roof hatches are made from corrosion-resistant aluminium and built to perform in harsh indoor and outdoor environments.

Their durable design suits facilities exposed to extreme heat or cold, including cold storage plants, coastal buildings, and industrial sites, ensuring long-term reliability without compromising safety.

FREQUENTLY ASKED QUESTIONS

Our Height Safety expertise identifies the best safety and compliant access solutions for your building access needs.

We audit and assess your roof safety and find the quickest and most cost-efficient solutions for your building and facility.

Our roof access systems are Australian-made, compliant and durable.

We are manufacturers of roof hatches and other access systems, which are preassembled to reduce on-site work time to minimise installation duration on your site.

By understanding the system's function, applications, and benefits, you can make an informed decision about the right roof hatch for your needs.

Contact us today.