HVAC Access Plant Decks, Platforms and Screens

Safetylyne specialises in designing and manufacturing lightweight, structural aluminium plant decks and platforms for HVAC systems, mechanical plants, and air conditioning equipment.

Proudly designed and manufactured in Australia, these platforms are designed for safe, compliant and easy access for installation, servicing, and maintenance.

Our access systems can be customised to meet the unique requirements of your project, providing practical and durable solutions for complex site layouts and HVAC equipment positioning and configurations.

Protecting Your Roof and Equipment

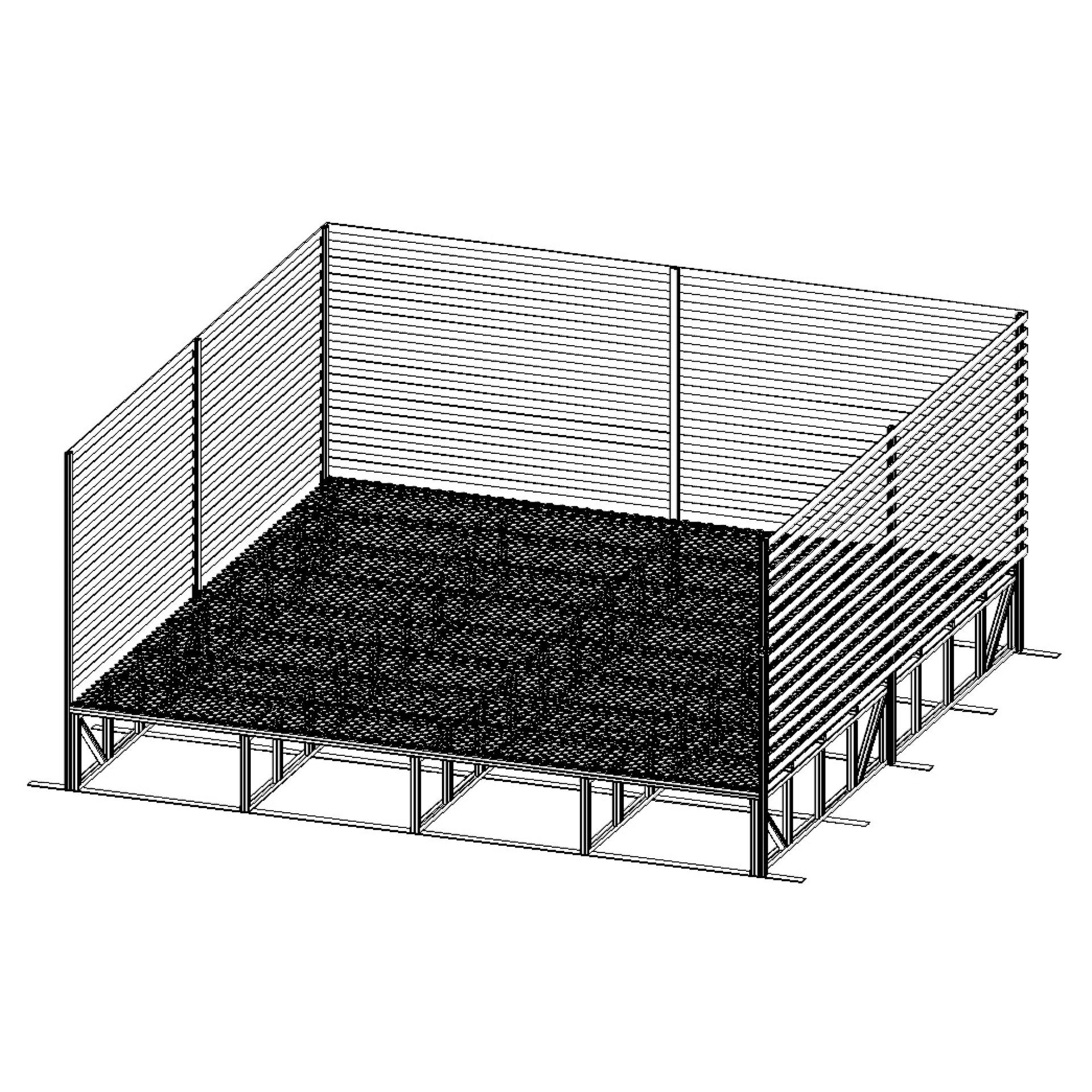

Safetylyne plant decks are structural platforms that secure HVAC equipment while protecting the roof’s integrity. They distribute concentrated equipment loads evenly, reducing stress on roof structures. Installed using waterproof, non-penetrative or fully sealed fixing methods, plant decks maintain roof watertightness and help prevent long-term leak risks. By elevating equipment, these platforms also allow adequate airflow around units, supporting system performance and reducing heat transfer to the roof surface.

Everything You Need to Know About Plant Platforms

+ Design and Structure

Plant platforms are usually fabricated from aluminium for its exceptional durability, corrosion resistance in harsh environments, and lightweight properties to reduce roof and surface load.

What is the best material for roof access plant systems?

At Safetylyne, we primarily work with aluminium materials to ensure maximum durability due to corrosion resistance and light weight.

Distributed-load aluminium HVAC decks reduce structural impact by dispersing equipment weight across engineered contact points rather than concentrating stress on roof surfaces.

Safetylyne designs and manufactures custom HVAC decks and plant platforms tailored to meet the specific needs of your facility. This includes size, load capacity, and additional features like

guardrails, gates,

access stairs and

access anchor points,

roof access ladders etc,

+ HVAC Platforms Installation

Professional Installation is crucial to ensure the safety and functionality of plant decks. Our experienced team ensures that your plant deck is installed correctly, meeting all safety and compliance standards for works at heights and meet necessary

roof safety regulations.

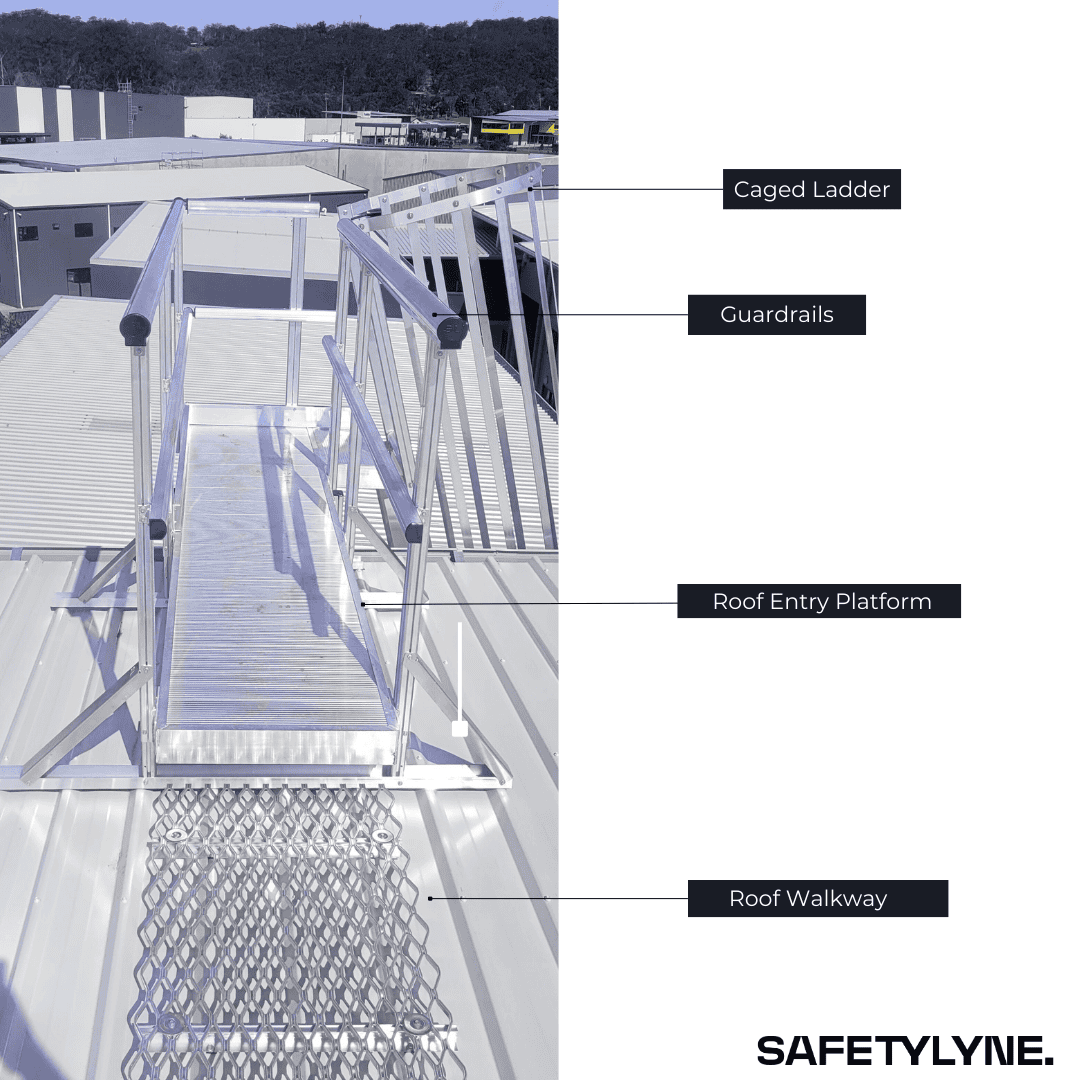

Plant decks can be integrated with other safety systems such as ladders, walkways, and guardrails to provide a comprehensive access solution.

+ Certification

Once installation works are completed, Safetylyne provides certifications for the completed access projects. Our height safety specialists ensure that plant decks comply with relevant safety standards and regulations, such as AS/NZS 1657 for fixed

platforms,

walkways,

stairways, and

ladders. Safetylyne also provides

certification for our access systems, ensuring they meet all necessary safety and quality standards with up to 25-year warranty.

Structural plant decks support heavy mechanical equipment and create a stable, elevated workspace for maintenance. These platforms rely on engineered framing and load-rated components that transfer weight safely into the building structure.

Safetylyne engineers design bespoke access platforms for your plant equipment, we manufacture these systems in-house in Australia and install these plant decks at your site with minimum project downtime.

Roof Plant Platforms with Custom Finishes

At Safetylyne, we offer plant platforms with a variety of finishes and colours to match your building's aesthetics. Our platforms can be customised to complement the overall look of your structure and to match project specifications.

Roof Plant Platform Screen Variations

Our platforms are available with various types of screen variations. You can choose between batten screens or louvre screens options.

- Batten Screens

Batten screens provide ventilation and partial visual screening for plant equipment. They are typically used where airflow is required but full concealment is not necessary. - Louvre Screens

Louvre screens are designed with angled slats to increase visual coverage and assist with noise reduction, while maintaining consistent airflow. They are suitable for applications where greater screening of equipment is required without compromising ventilation.

How Louvre Screens Enhance Sound Isolation

Noise Reduction with Custom Louvre Screens for HVAC and Industrial Equipment.

Louvre screens are a great solution for reducing noise from rooftop and industrial equipment such as HVAC units, generators, air conditioning systems, exhaust fans, cooling towers, air compressors, pumps, and industrial machinery etc.

Angled louvre blades are designed to block and redirect sound waves, providing effective sound treatment without sacrificing the airflow. This feature helps create a quieter environment, reducing the impact of operational noise on surrounding areas like offices, residential buildings, and public spaces.

These screens act as a sound barrier, minimising the noise impact that can affect employees, nearby residents, or neighbouring businesses. By diffusing and deflecting sound and creating an acoustic barrier, louvre screens ensure that operational noise is kept to a minimum while maintaining ventilation and system efficiency.

We design and manufacture custom acoustic screens designed to optimise sound isolation.

This is how you can achieve balance between practicality and sound reduction, enhancing both functionality and comfort for your building.

For example, one of our recent roof access projects in the Sunshine Coast combined plant decks with integrated acoustic louvre screens to manage HVAC noise while maintaining safe roof access. The system provides effective noise reduction and full compliance.

This is how you can achieve balance between practicality and sound reduction, enhancing both functionality and comfort for your building.

Ensuring Safety and Compliance:

The Essential Standards for Plant Decks and Platforms in Australia

In Australia, plant decks and platforms must be designed and installed in full compliance with relevant standards and regulations. Aligning with Australian standards is essential to meet structural integrity and workers' safety requirements across all stages of the process.

Relevant Standards for Plant Decks and Platforms

+

AS 1657

– Fixed platforms, walkways, stairways, and ladders

This standard outlines the design requirements for safe access to plant and equipment on platforms, walkways, and stairways. It specifies the correct dimensions, guardrails, and other safety measures required to prevent falls and ensure stable access.

+ AS/NZS 1170 – Structural design actions

This set of standards provides guidelines for the structural design of plant decks and platforms, particularly concerning load capacity and wind actions. It ensures that platforms can support the necessary weight while withstanding environmental factors like wind loads and vibrations.

+ AS/NZS 1891 – Industrial fall-arrest systems and devices

If plant platforms are located in elevated areas, consider that this standard applies to the use of fall protection equipment, ensuring that appropriate anchor points and fall-arrest systems are installed where necessary.

+ AS 4100 – Steel Structures & AS 1664 – Aluminium Structures

These standards set out the structural requirements for platforms made from steel and aluminium, respectively, ensuring that materials and fixing methods used are appropriate to withstand environmental conditions, functionality, and load requirements.

+ National Construction Code (NCC)

The NCC sets out the broader regulatory framework for all types of construction, including plant platforms. It incorporates standards related to safety, durability, and structural integrity, ensuring that platforms comply with building codes and regulations.

Visit the Regulations and Guidelines page for detailed information on roof safety and to learn more about compliance with Australian Standards.

All Safetylyne plant platforms and decks are designed and installed in compliance with these standards to ensure the highest level of safety and structural integrity.

Safe andcompliant

mechanical plant room access is essential for elevated platforms, with conforming platforms, stairs, and guardrails to support ongoing maintenance.

We also provide comprehensive building safety audits and advice on meeting these standards during the design and installation phases, ensuring that your facility is compliant and secure for ongoing maintenance and operations.

Roof Entry Platforms

Sometimes, roof entry platforms can be confused with plant decks, while they serve a different purpose.

The difference between a roof entry platform and a roof platform:

Instead of supporting equipment, these compact platforms provide a safe landing point at the top of a roof ladder or stairs.

They connect directly to roof walkways and are typically fitted with guardrails, providing a compliant and safe transition for workers accessing HVAC units, solar panels, or other roof-mounted equipment.

Why Safetylyne Plant Decks are a Smart Choice for Your Site??

Unlike most of the traditional platforms, Safetylyne plant decks are designed for minimal-impact installation, using fewer fixings and roof penetrations. This approach helps protect the roof membrane and reduces the risk of issues like corrosion and water ingress.

Constructed from lightweight, non-corrosive aluminium, this plant access system acts as a load-distributing raft, reducing point loads and limiting structural impact on the roof.

Engineered fixings are designed to meet structural and wind load requirements while minimising roof penetrations. This makes the system safer for sensitive roofing systems and quicker to install.

This lightweight, low-impact design leads directly to faster, more efficient project delivery.

For example, here is how our team installed a plant deck system with screens and a full roof safety setup in just one day on a commercial warehouse roof in Dalby.

The solution solved the challenge of having no existing roof safety systems and delivered a safe, compliant access platform ready for immediate use.

Choose Australian-Made Compliant HVAC Platforms With Safetylyne

We fabricate all systems at our warehouse to reduce installation time on site for a quick and seamless installation process.

With decades of industry experience, we are committed to delivering high-quality solutions tailored to your specific needs.

See how our modular aluminium plant platforms are delivered and installed without interruptions

When a Plant Deck Can Be Required in Your Facility?

+ Supporting Heavy Equipment

Facilities that have a need for heavy machinery installation and maintenance access (eg., HVAC systems, generators, cold storage units, large solar panel systems, or any large industrial plant equipment) benefit significantly from plant decks and platforms.

These fixed platforms are engineered to support substantial loads, ensuring the stability and safety of the equipment, ensuring free airflow, and sound isolation when required.

+ Improving Accessibility

Fixed roof decks provide easy and safe access to mechanical equipment, allowing access for regular maintenance, inspections, and repairs. This is especially important in facilities where equipment is installed at height or in hard-to-reach areas like elevated areas, mezzanines, rooftops and plant rooms.

+ Enhancing Safety

By providing a stable working surface, plant decks enhance roof safety access and height safety, reducing the risk of accidents and injuries on-site.

They often include features like guardrails, non-slip surfaces, walkways, screens and secure access points, and rooftop gates, ensuring a safe working environment for maintenance workers.

Some plant decks and platforms may require doors and stairs for enhanced access and security, providing safe entry points to enclosed areas or elevated equipment.

+ Pitched Roof Access Platform

Plant decks can be designed and engineered to suit project-specific roof pitch requirements.

We assess every HVAC system, air conditioning, cooling towers, mechanical plant rooms, other mechanical plant equipment areas, and building design to recommend the most efficient and compliant system for your site and roof.

This ensures safety and compliance with relevant regulations, creating an optimal and secure environment.

+ Optimising Space

Plant decks help in organising and optimising the available space on rooftops and mechanical plant rooms.

By elevating equipment, they free up valuable ground space for other uses, reduce clutter, and provide an even surface for roof safety access, maintaining the air flow and surface load.

+ Compliance with Regulations

Many safety and building regulations require the installation of plant decks for specific types of equipment. Ensuring compliance with these safety regulations is essential for the safety and legality of your operations.

+ HVAC Noise reduction

Plant Platforms with louvre screens provide an acoustic barrier to isolate HVAC and any other equipment and machinery noise while maintaining a free airflow.

CONTACT OUR HEIGHT SAFETY EXPERTS TODAY