Safe Access Solutions

For Cold Storage Facilities

Cold rooms, freezers, and temperature-controlled warehouses demand access systems that balance hygiene, safety, and efficiency.

The right systems reduce product loss, prevent condensation and ice, and keep people and equipment moving, all while meeting compliance requirements.

Safetylyne designs, engineers, manufactures and installs compliant access systems for both new facility designs and upgrades to existing sites.

Every solution is built for long-term safety, performance, and compliance, trusted by architects, builders, designers, and facility managers across Australia.

From concept through installation and maintenance, we help create cold storage environments that protect people, maintain product quality, and keep operations running smoothly.

Access Systems Options For Cold Storage Warehouses:

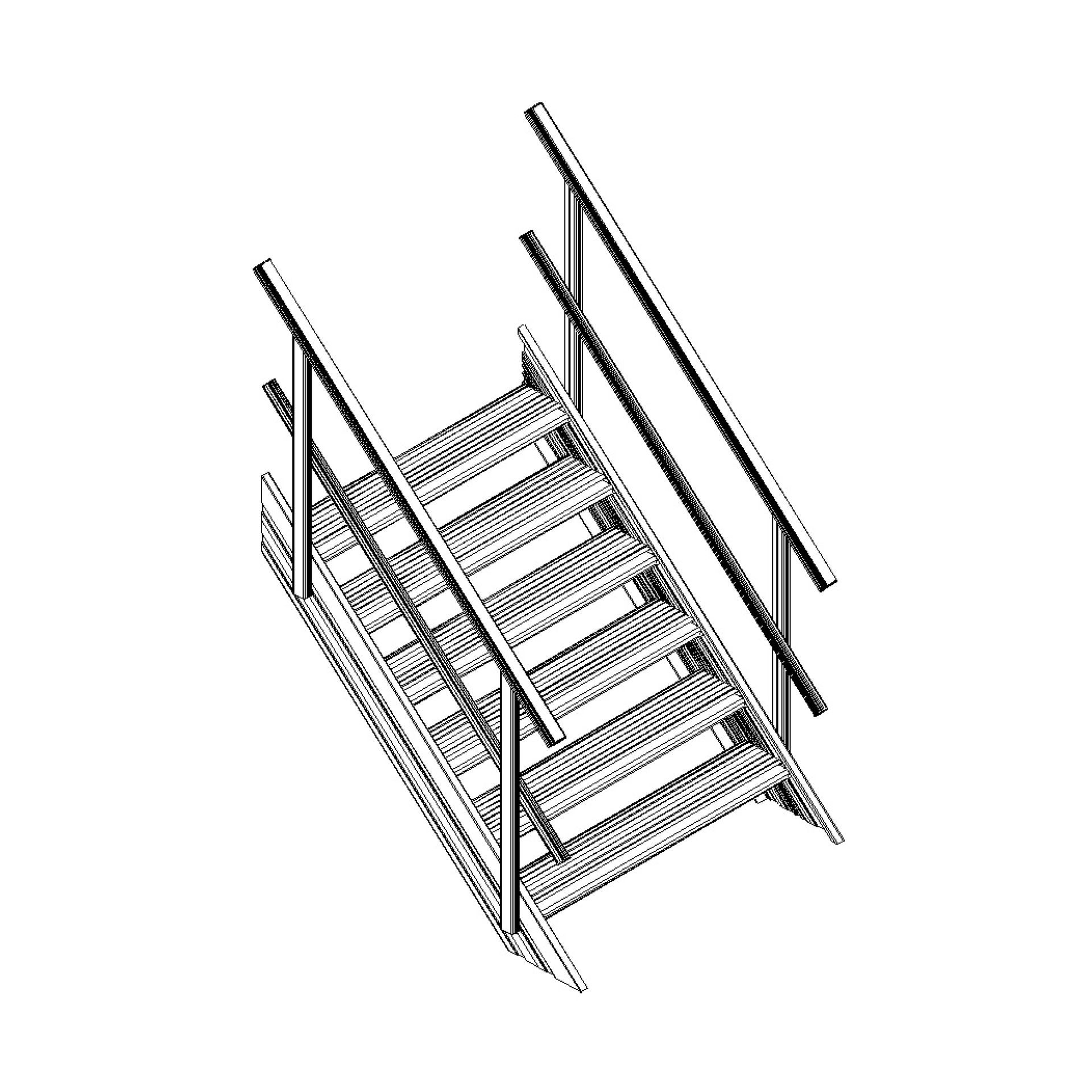

+ Stairs and Roof Access

Lightweight, corrosion-resistant aluminium stairs are ideal for food-grade and low-temperature environments.

Fixed ladders, brackets, and stair towers provide safe roof access to HVAC equipment, compressors, alcove units, penthouse systems, and refrigeration plant. These systems are engineered to match site conditions and minimise roof damage during installation.

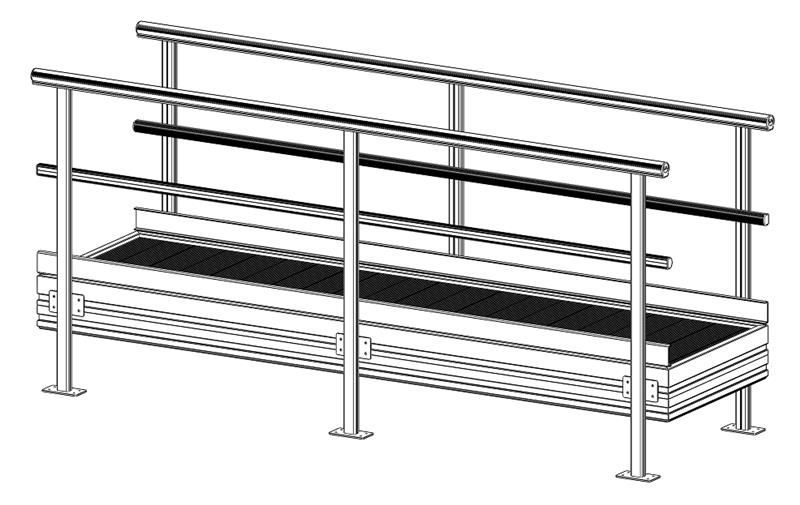

+ Guardrails and Fall Protection

Guardrails, handrails, and edge protection prevent falls in elevated or high-traffic areas such as mezzanines, platforms, and loading docks. Where guardrails cannot be installed, static lines and anchor points are used with PPE for fall restraint or arrest.

+ Static Lines and Anchor Points

Installed by certified professionals, static lines and anchor points provide secure connections for harnesses when working on plant decks, evaporator units, condensing units, or elevated refrigeration systems. These systems are designed for sub-zero conditions and inspected regularly for compliance.

+ Ladder Systems

Fixed ladders, caged ladders, and mobile ladders provide safe access where stairs or walkways aren’t practical. Ladder brackets improve stability in frequently used areas, and all systems are built to handle cold, damp, or corrosive conditions.

+ Plant Decks / HVAC PLATFORMS

Custom plant decks and platforms provide slip-resistant access to HVAC, refrigeration, and penthouse equipment. These improve safety for maintenance teams, reduce the risk of slips, and support efficient servicing.

Q&A: Understanding Your Access Needs

Cold Storage Access Considerations

Facilities often rely on PIR sheeting for refrigeration, making access to the compressors and refrigeration systems above cold rooms or in the ceiling cavity more complex.

Purpose-designed platforms, walkways, and step-over systems prevent damage to insulated panels while giving maintenance teams safe, compliant access routes.

Many sites also require crossover access for refrigerant pipework and glycol lines, as well as stairs over pump stations and valve stations. These engineered systems protect critical services and provide safe pathways for technicians.

In large cold storage and distribution centers, access stair towers ensure safe roof access to HVAC equipment, alcove units, penthouse systems, evaporator units, and condensing units.

We also design walkways to penthouse units and service routes for fans and rooftop plant, ensuring maintenance tasks can be completed efficiently and without risk to insulated panels.

Ammonia Systems and Evacuation Design

For facilities using ammonia refrigerant systems, access planning must also include the design of safe evacuation routes. In the event of an ammonia leak or fire in the roof space, stair towers, walkways, and emergency egress systems provide reliable routes for safe evacuation. Early integration of evacuation design ensures compliance, reduces risks, and keeps facilities audit-ready.

Emergency Evacuation Essentials In Cold Storage Facilities:

- Clear egress routes

- Safe stair towers & walkways

- Bypass ammonia systems, refrigerant pipework, glycol lines

- Plan for fire & roof-space leaks

- Built into design from day one

Conveyor Access in Cold Storage

Access platforms, step-over bridges, gantries, and guardrails are essential for safe and compliant interaction with conveyor systems in freezer and chiller warehouses.

- Non-slip aluminium platforms and stair bridges for servicing

- Elevated gantries and crossovers to move safely over conveyors

- Guardrails, toe boards, and safety gates to prevent slips and falls

- Step bridges configured for safe ingress/egress and servicing

These solutions reduce fall risk, improve ergonomics, and ensure conveyor access remains safe in sub-zero conditions while keeping systems compliant with AS/NZS 1657 and AS/NZS 1891.

Industry Trends in Cold Storage Access & Safety

- Safer Access for Complex Facilities – Custom stairs, ladders, walkways, gantries, and step-overs for elevated or restricted areas.

- Space-Saving Plant Decks – Maximise usable space for equipment installations.

- Corrosion-Resistant Solutions – Aluminium and FRP resist moisture and extreme temperatures.

- Built-In Compliance – Designed to meet or exceed AS/NZS 1657 and related standards.

- Sustainable Design – Long-life, non-corrosive systems reduce maintenance and replacements.

- Integrated Stair Towers – Provide regular access to rooftop plant and form part of compliant fire escape and evacuation design.

See How We Solved Complex Cold Storage Roof And Ceiling Access Challenges with SPB:

Contact Us

For top-quality, custom-engineered access solutions for your cold storage facility, contact Safetylyne today. Our experts are ready to provide comprehensive safety audits, recommendations, and installations to ensure the highest level of safety and efficiency for your operations.

Contact Us

Compliance and Installation for Cold Storage Safety

Cold storage facilities present unique risks, from slippery surfaces to restricted spaces.

That’s why it’s essential that access systems - including platforms, guardrails, and ladders - are designed and installed to meet Australian safety standards.

Professional installation plays a critical role in ensuring your systems are not only compliant but also safe and reliable in demanding cold storage environments.

Safetylyne’s certified team delivers expert installation services, helping your facility meet all regulatory requirements while supporting long-term operational safety.

Cold Storage Access Projects

Access Solved for industrial cold storage facilities.

Our Process

Engineered Systems

Our Engineered Systems are a range of meticulously designed and manufactured products that can be integrated into a comprehensive height safety package, custom access solution or supplied individually based on client needs. These products, are manufactured in-house to the highest standards and are not only versatile, reliable and meet industry standards but also exceed client expectations.

They are Access Solved.