Plant Room Access Solutions

Plant Room Access: Safe, Practical Solutions for Essential Maintenance

Engineered access systems for plant rooms ensure safe, compliant exit and entry to critical building services for personal and plant equipment.

From rooftop units to internal mechanical equipment plant rooms, these custom solutions support safe movement in tight or elevated areas - reducing risk, improving maintenance efficiency, protecting infrastructure and personnel risk.

Plant Room Access Solutions

Safe, Efficient Access to Building Services and Critical Equipment.

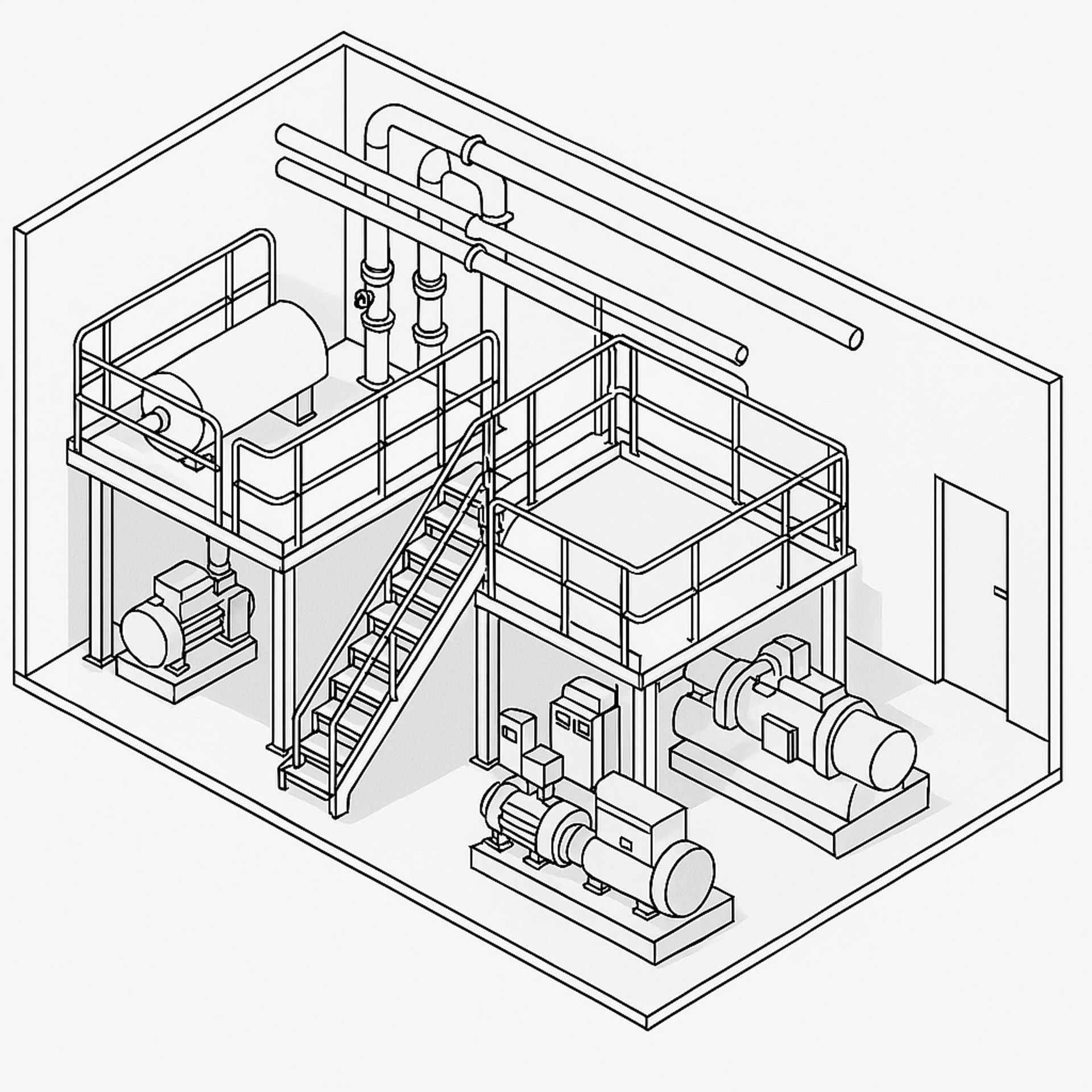

Plant rooms house the systems that keep buildings functioning - mechanical services, electrical boards, HVAC units, water pumps, and more. These areas often require regular maintenance but are typically located in difficult or elevated positions, with restricted space and limited built-in access, creating logistical challenges for both service technicians and equipment. Without the right access infrastructure, every routine inspection or repair can become a safety risk and a logistical challenge.

That’s where engineered access systems make the difference.

Planning Safe and Efficient Plant Room Access

Coordinating access within a mechanical plant area or MEP (Mechanical, Electrical, and Plumbing) plant room requires careful planning from the early stages of design.

Plant room accesses are often poorly configured due to the plant equipment sizing, configuration, and limitations of space and structural constraints of the building.

When access pathways aren’t considered early, maintenance can become hazardous or near impossible.

A good rule of thumb is to coordinate plant room layout in partnership with both mechanical engineers and building access specialists.

Ensure that clearances for all major equipment are defined early, and identify any areas where elevated access - such as crossover stairs or ladder - will be required to reach valves, ducting, or control panels.

Always leave space for retrofitting fall prevention systems like anchor points, step platforms, or handrails.

Plant Room Designing Principles:

What You Need to Know

Designing a compliant and functional plant room starts with safety, accessibility, serviceability and suitable control measures at its core.

In Australia, standards like AS/NZS 1657:2018 and the National Construction Code (NCC) provide a regulatory framework, but practical design choices make the difference between a smooth operation and a daily safety risk.

Key Design Principles

- Plan for Access Early

Always coordinate the layout of services with access in mind. If HVAC units, pumps, or switchboards can’t be safely reached for maintenance, they’ll eventually become a hazard - or a costly problem.

Incorporate platforms, stairs, and walkways during the design phase, not as an afterthought, while also factoring in frequency of access considerations to ensure the right level of safety and practicality for ongoing service needs.

- Maintain Clearances

Ensure there’s enough room for personnel to move safely around equipment. As a rule, aim for a minimum 600mm clearance around major plant, and provide fixed access solutions. For example, stairs or step platforms may be required where vertical access is needed, with suitable clearances provided for landings and circulation spaces.

- Protect Service Areas

Don’t route walkways directly over sensitive pipes, cables, or ducts. Use crossover stairs, step bridges, walkways, and modular platforms to create a designated path of access that guides foot traffic safely and protects infrastructure from accidental damage.

- Design for Safe Egress

Emergency exits must be clearly marked and unobstructed. Avoid placing equipment or access systems where they could block escape paths during servicing or emergencies.

- Comply with Australian Standards

Fall protection, edge protection, and ladder systems must meet AS1657:2018 requirements. Where fall arrest systems are used, ensure they are inspected and certified annually under AS/NZS 1891.4:2009 and AS5532:2013

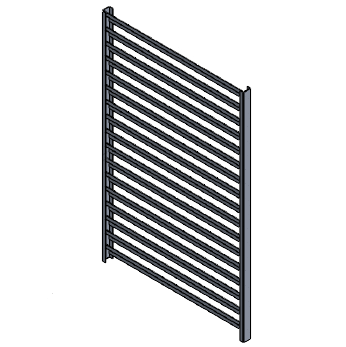

- Minimise Noise Impact

External plant rooms and mechanical systems - such as those housing HVAC units, pumps, or filtration equipment - must be acoustically treated to minimise noise impact. This includes the use of acoustic screens or enclosures and carefully positioning noise impact away from boundaries, operational workspaces, or noise-sensitive areas.

Safetylyne Tip

Working in tight plant rooms doesn’t mean compromising on safety.

Our modular aluminium access systems are designed to integrate with your plant layout, offering compliant solutions without adding bulk or requiring structural changes.

Supporting Safer, More Efficient Maintenance

The right access system ensures that technicians, contractors, and maintenance personnel can reach critical equipment safely, quickly, and without disruption to surrounding infrastructure.

Whether located on a rooftop, mezzanine, or internally, access to plant areas must meet compliance standards and support repeat use over time.

Access solutions for Plant rooms include:

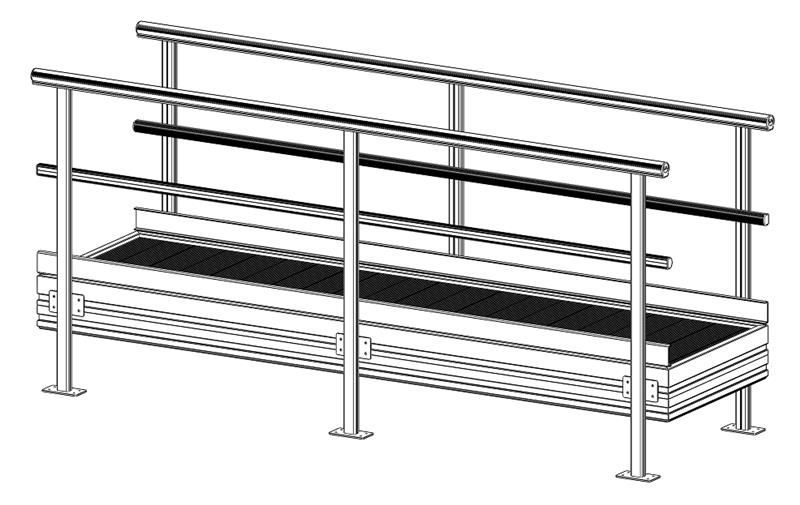

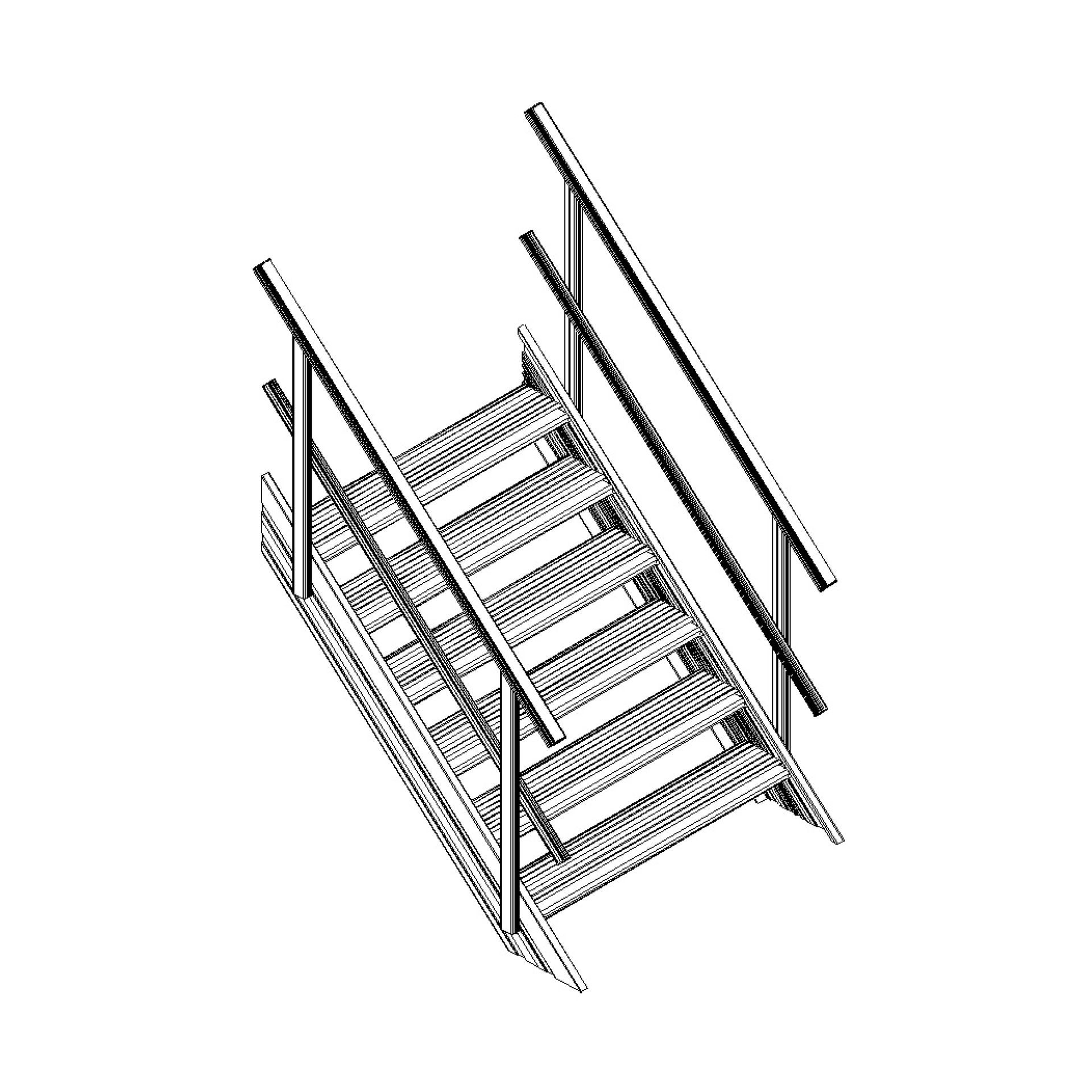

- Fixed aluminium stairs for elevated plant rooms or platforms

- Modular walkways and grated platforms for safe movement or suspended decks

- Step-over and crossover units to bridge pipes, ducts, or cables

- Low-profile ladders for compact or enclosed spaces

- Guardrails and barrier systems to reduce fall risks

- Static lines and anchor points where fall restraint is required

All our systems are built from lightweight, corrosion-resistant aluminium and stainless steel, making them durable, low maintenance, and easy to integrate into existing structures.

Designing Plant Room Access That Works, And Keeps Workers Safe

- Reduces risk of slips, trips, and falls in areas with limited clearance or uneven footing

- Improves maintenance workflows, allowing contractors to access services without temporary ladders, scaffolds, or unsafe workarounds

- Protects roofs and infrastructure by clearly directing foot traffic away from sensitive surfaces

- Ensures compliance with AS/NZS 1657 and WHS codes for safe access and working at height

- Minimises downtime and repair costs by supporting faster, safer, and more convenient servicing of critical equipment

Applications

Plant room access systems are essential for:

- Rooftop air handling units (AHUs)

- Electrical and switchboard rooms

- Cooling towers access and mechanical services

- Water systems and fire control infrastructure

- Industrial plant decks and raised platforms

- Hospital, commercial, and data centre buildings with complex service layouts

These systems are frequently used in both new construction and retrofitting projects to improve the safety and functionality of plant maintenance zones.

Australian Safety Regulations for Plant Room Access

In Australia, mechanical plant room access is governed by a mix of safety, design, and compliance standards. Key regulations include:

- AS 1657:2018 – Governs fixed platforms, walkways, stairways, and ladders, specifying safe design for access systems.

- AS/NZS 4801 (OHS Management Systems) and ISO 45001 – Emphasise risk mitigation and safety management, including safe access provisions.

- National Construction Code (NCC) – Requires safe access to and within plant rooms, particularly in commercial and industrial buildings.

When vertical fall protection is required (e.g. lifeline systems), AS/NZS 1891.4:2009 outlines selection, use, and maintenance standards. These codes collectively ensure that plant rooms are not only functional but also safe for the personnel accessing them regularly.

Restricting Access to Authorised Personnel

Controlled access is often overlooked in plant room design, but it’s a key part of compliance and risk management.

In high-risk areas like plant rooms, it's critical to ensure only trained and authorised personnel can access equipment. Uncontrolled access increases the risk of injury, equipment damage, and non-compliance with safety regulations.

To meet compliance and best practice standards for mechanical plant, the following systems can be incorporated:

Access Control Solutions:

- Lockable Gates

Install self-closing, lockable gates at entry points to ladders, stairs, or elevated platforms. These prevent casual or accidental access and are compliant with AS 1657:2018 when used with guardrail systems.

- Ladder Lockout Systems

Fixed ladders can be fitted with ladder lockout kits to restrict use. These are ideal for vertical access points leading to rooftops or mechanical zones.

- Signage and Access Protocols

All entry points should display warning signage indicating restricted access and required PPE. These visual controls support WHS obligations and reinforce site rules.

- Electronic Access Control (Optional)

For critical infrastructure or facilities with centralised access control, swipe cards or keypad systems can be integrated with plant room doors or gates.

Frequently Asked Questions About Plant Room Access

CONTACT OUR TEAM OF HEIGHT SAFETY EXPERTS

Let's chat about your plant room access solutions