Acoustic Louvre Screens

Acoustic louvre screens are a practical solution for HVAC to improve both airflow and noise control.

These Acoustic HVAC screens are designed to reduce sound transmission while maintaining ventilation. They create quieter, compliant environments across commercial and industrial sites.

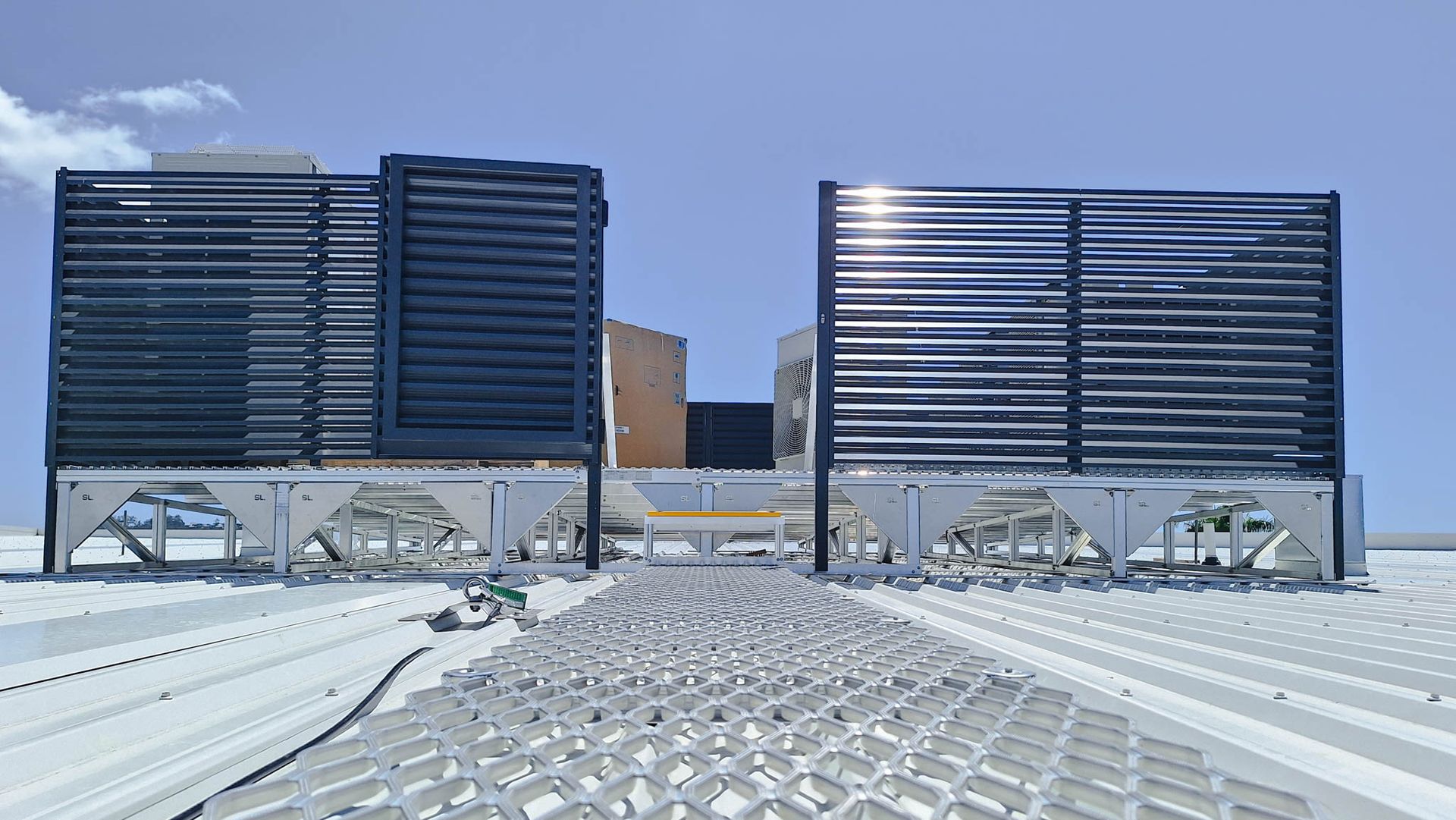

These louvre systems integrate seamlessly with plant decks and rooftop platforms or stand alone as effective noise barriers.

Every design prioritises safety, structural integrity, and long-term reliability, even in the toughest environments.

Acoustic louvre screens are aesthetic and sound barriers designed to reduce noise from mechanical plant while allowing essential airflow.

Commonly installed around roof HVAC units and other plant equipment, these screens help manage sound levels without compromising ventilation or access.

Acoustic screens can be integrated with plant decks and rooftop access systems, for compliance, safe maintenance access, and environmental control.

These access systems are ideal for commercial buildings, hospitals, data centres, and high-density urban developments.

Acoustic Louvre Screens for HVAC and Plant Equipment Sound Isolation

An acoustic louvre barrier is an effective solution for controlling noise from mechanical services such as HVAC units, air conditioning systems, cooling towers, and other plant equipment. These systems are designed to strike the right balance between acoustic performance, ventilation, and service access.

When do you need an acoustic screen for your HVAC equipment?

+ When noise impacts surrounding areas

If sound from roofs or ground-mounted plant affects nearby offices, classrooms, or residences and other noise-sensitive environments like hospitals, HVAC sound screens help reduce transmission without restricting airflow.

+ When airflow and performance must be maintained

Some of the traditional barriers can trap heat or reduce ventilation.

Louvre blades are designed to deflect noise while allowing air circulation - ideal for equipment that relies on consistent airflow.

+ When site layout demands a

custom HVAC access solution

These acoustic screens can be designed to fit around complex plant decks, enclosed platforms, or tight rooftop spaces, ensuring safe access and compliance without disrupting the system layout.

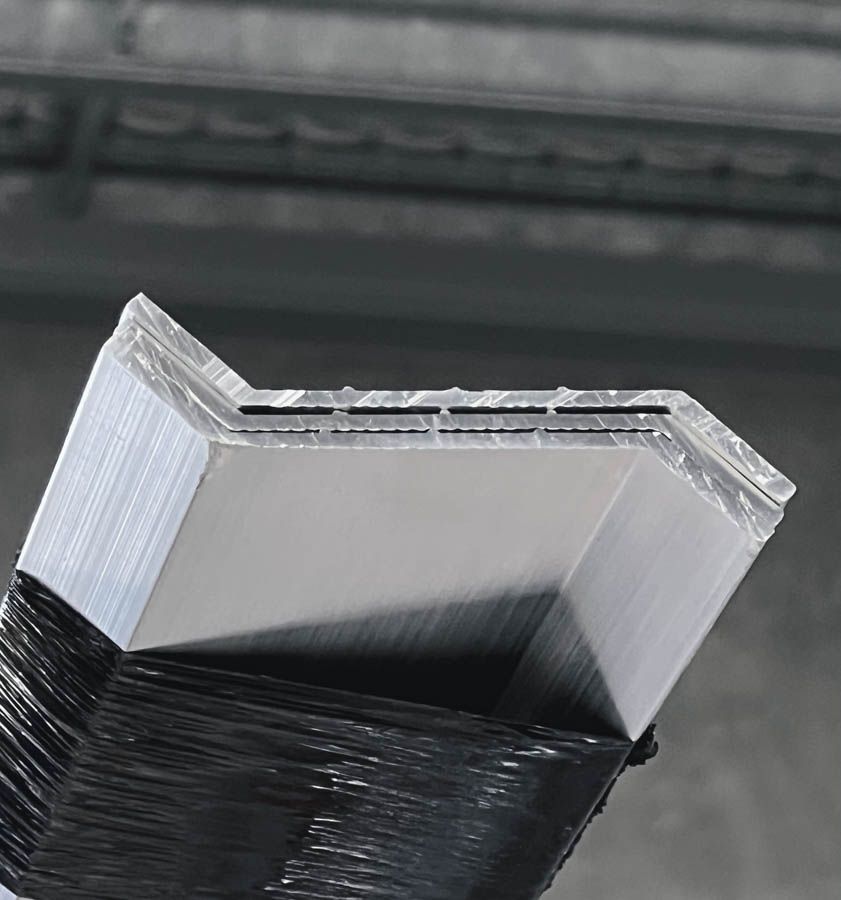

+ When durability and long-term exposure matter

In harsh or coastal environments, powder-coated aluminium or galvanised steel screens resist corrosion, UV exposure, and weathering for reliable performance over time.

+ When compliance and safety are required

All systems are engineered to meet

Australian Roof Safety Standards, including structural and wind load requirements for rooftop installations. Integration

with roof walkways systems and other

height safety systems provides safe, practical servicing.

Designed for Performance, Compliance, and Aesthetic Integration

In addition to noise control and airflow optimisation, acoustic louvre screens can also contribute to the architectural appearance of a site.

Powder-coated finishes are available in both standard and custom colours - including the most popular access system colour finishes in white, light grey, dark grey, black, and dark blue.

This allows screens and roof safety systems to blend seamlessly with surrounding façades, rooftop lines, or branded colour schemes.

For visual concealment, to meet council acoustic requirements, or to match project design standards - Safetylyne delivers solutions that meet both functional and aesthetic expectations.

All acoustic screen systems are designed and engineered in accordance with relevant Australian Standards, including AS/NZS 1170 for structural loading and wind performance.

Acoustic ratings can be tailored to suit project-specific requirements, and Safetylyne works with consultants, builders, and facility managers to ensure documentation is in place for compliance at every stage.

End-to-End Capabilities for Complex Sites

Safetylyne provides complete solutions that integrate acoustic louvre screens with elevated plant decks, walkways, access stairs, handrails, and fall protection systems. This simplifies project coordination by consolidating the structural, safety, and acoustic components into a single engineered system - ideal for retrofit upgrades or new construction projects.

Our team specialises in overcoming access challenges on rooftops and tight mechanical zones, providing practical and long-lasting systems that are easy to install and maintain.

Contact Our Height Safety Experts today