Edge Protection Systems

Roof Edge Protection for Commercial & Industrial Buildings

Roof edge protection on commercial and industrial buildings needs more than a compliant barrier. It has to integrate with the roof profile, perform for decades, and support safe movement around plant and equipment without disrupting operations.

That’s why permanent, engineered aluminium systems remain the benchmark for long-term safety.

This page covers the best roof edge protection systems for commercial buildings, how to compare permanent vs temporary solutions, and what matters most when choosing an edge protection system for industrial environments.

Best Roof Edge Protection Systems for Commercial Buildings

The strongest-performing systems consistently share three common features:

engineered design, modular aluminium construction, and integration with other height safety systems, eg walkways or platforms.

Common roof access system to consider for your roof edge protection:

1. Permanent Aluminium Guardrails (roof edge protection)

Offer the highest reliability for large rooftops, plant areas, loading bays, and industrial facilities with permanent guardrails. These systems maintain performance even on harsh industrial sites if choosing non-corrosive aluminium.

2. Walkway-Integrated Roof Edge Protection

Guardrails fixed to an aluminium walkway keep workers on a defined route, minimise roof loading, and deliver a clear access path to plant and equipment.

3. Custom Roof Edge Protection Systems for Unique Architectural Designs

Complex roof geometry, concealed fixings, non-standard facades, or high-spec finishes often demand custom rails designed specifically for the project.

Differences Between Permanent and Temporary Roof Edge Protection

Temporary systems

- Short-term use

- Clunky steel frames

- High visual impact

- Not suited for ongoing maintenance

- Usually non-compliant for permanent facility operations

Permanent aluminium systems

- Corrosion-resistant

- Light and strong

- Clean aesthetic

- Low maintenance

- Designed for decades of use

Permanent systems outperform temporary options in both safety and life-cycle cost for industrial and commercial buildings.

Benefits of Modular Roof Edge Protection Systems

Modular systems simplify everything from design to installation:

- Fast, clean installation and minimum site disruption

- Consistent quality with factory-prefabricated components

- Proven roof fixings for metal profiles

- Easy to integrate with walkways, step-bridges, ladders or platforms

- Long-term flexibility for future upgrades or layout changes

When combined with aluminium construction, modularity gives facilities a system that remains safe and stable without heavy loads on the roof structure.

How to Choose the Right Roof Edge Protection for Industrial Buildings

Heavy plant, constant maintenance, high-fall risk areas, and complex service layouts add extra pressure in industrial buildings.

That is why it is important to prioritise systems that deliver the following:

- Full compliance with AS 1657 and relevant fall protection standards

- Non-corrosive materials suitable for food processing, cold storage, and coastal sites

- Low-maintenance performance for long-term operations

- Integration with the entire height safety system (access ladders, hatches, structural access walkway platforms, static lines, anchors)

- Clear, logical worker movement paths

- Certified engineering to suit the building’s structural capacity

Systems must also be user-friendly: predictable layouts, stable handholds, no trip points, and smooth transitions between access components.

Safety Standards Compliance for Roof Edge Protection Products

A compliant system should always demonstrate:

- AS 1657 compliance for guardrails, walkways, ladders, and platforms

- Engineering documentation for fixings, loads, and structural interfaces

- Safe approach distances to the roof edges and plant equipment

- Correct heights, toe board requirements, and barrier configurations

Australian-made systems offer an advantage here - manufacturing to strict local standards ensures world-class safety and durability.

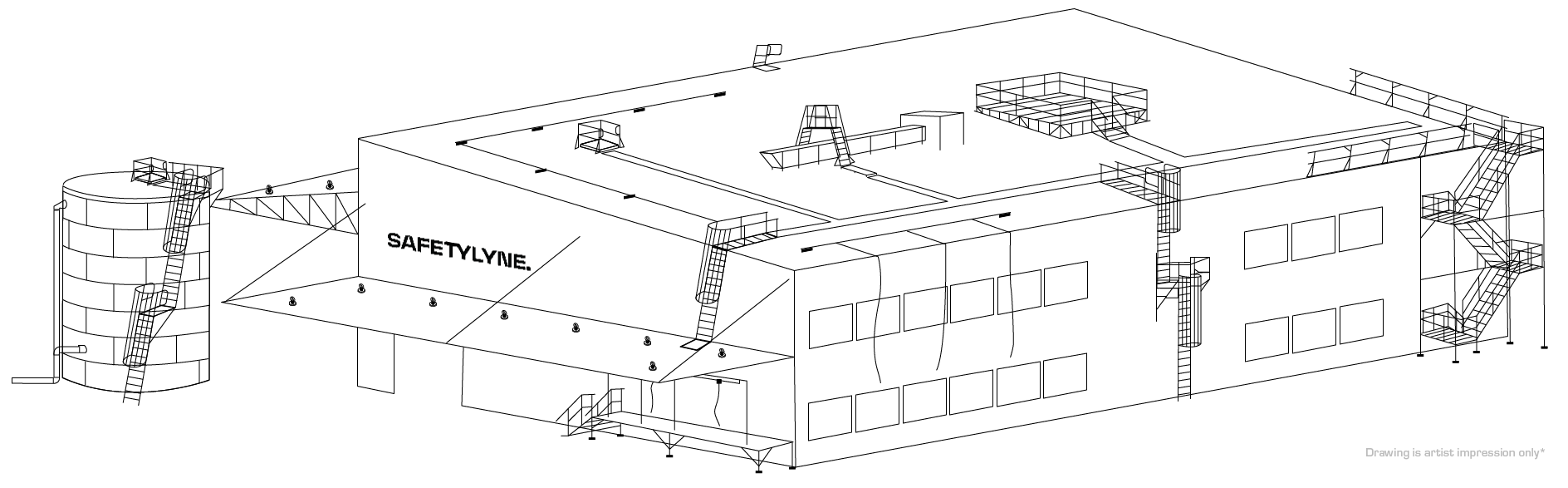

Edge Protection Project Examples In Situ

1. DISTRIBUTION CENTRE EDGE PROTECTION DESIGN AND INSTALLATION

case study

Challenges

A warehouse facility required a controlled and compliant edge protection design for roof access and for an internal cold storage unit.

Safetylyne Solution

- Custom HVAC access platform for Fusion Modular units

- Edge Protection Guardrails mounted to coldroom structures

- Controlled roof anchor points with engineered fixing systems

- Engineered roof walkways

- Caged access roof ladders

The system created a complete, enclosed access route, combining roof edge protection with platforms and stepover bridges to ensure safe movement in an environment with strict hygiene and thermal requirements.

View full edge protection case study here

2. Private Hospital Roof Edge Protection + Roof Plant Access

Case Study

Challenges

Ongoing maintenance around sensitive rooftop plant, multiple edge exposures, and varied equipment layouts.

Safetylyne Solution

- Roof guardrails

- Access walkways

- HVAC Access Platforms

- Step-bridges

- Access ladders

- Anchors and static line system

Why it worked

Integrating guardrails with walkways and platforms created a structured flow around the rooftop. Workers could access all equipment safely without relying on temporary gear or PPE-only solutions.

Top Suppliers of Guardrails for Roof Edges in Australia

When researching edge protection options, choose Australia’s highest-performing suppliers who manufacture locally, meet strict engineering standards, and have been operating in the market for a long period of time.

Safetylyne is one of the only suppliers that designs, engineers, fabricates, and installs edge protection systems.

Fully modular aluminium access and edge protection systems - made in Australia and built for world-class safety.

This combination ensures every project receives a system tailored to its roof profile, building structure, and maintenance requirements.

Innovative Roof Edge Fall Prevention Products in the Market

Leading-edge solutions include:

- modular aluminium guardrails designed specifically for metal roofs

- walkway-mounted guardrail systems

- Integrated edge protection for plant decks

- concealed-fix architectural guardrails

- non-corrosive aluminium systems for food and cold-storage environments

These innovations reduce roof penetrations, simplify access, and create long-lasting fall protection without compromising the building’s appearance.

User-Friendly Roof Edge Protection Solutions

A system is user-friendly when it:

- is designed with the end user in mind, not just to tick the box

- supports natural movement

- connects walkways, ladders, and platforms without awkward transitions

- minimises trip risks

- offers stable handholds throughout

- requires minimal training to use correctly

- stays clear of services and equipment

- remains safe even with heavy maintenance tools