Understanding AS/NZS 1170 Standard Compliance

AS/NZS 1170 standard controls structural actions, loads that stairs, landings, handrails, and balustrades must safely resist.

Understanding how this standard applies to building safety design helps avoid redesigns, value engineering compromises, and late-stage compliance clashes.

WHAT IS AS/NZS 1170 IN SIMPLE TERMS?

AS/NZS 1170 is the structural loading standard used across Australia and New Zealand. It defines the actions structures must withstand, including:

- Dead loads

- Live loads

- Crowd loads

- Barrier and handrail loads

- Environmental actions

The most relevant part is AS/NZS 1170.1 for the stairs, which sets out imposed actions based on how a stair will be used.

WHY AS/NZS 1170 MATTERS FOR STAIR DESIGN

Stair systems can experience concentrated loads, directional movement, and crowd forces.

AS/NZS 1170 covers:

- Structural sizing of stair flights and landings

- Fixing design into slabs, walls, or steel

- Handrail and balustrade performance

- Material selection, especially lightweight vs structural systems

STAIR USE CATEGORIES AND LOAD IMPLICATIONS

The applied load depends on how the stair is used, not how it looks.

This includes:

- Public access stairs

- Fire egress stairs

- Service or maintenance stairs

- Restricted access stairs (often linked with AS 1657)

Higher public use generally means higher imposed loads and increased barrier requirements. This directly affects member sizing, deflection limits, and connection detailing.

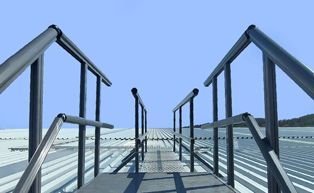

HANDRAILS AND BALUSTRADES UNDER AS/NZS 1170

- Horizontal line loads on handrails

- Point loads for crowd pressure

- Higher load categories for areas subject to crowding

This is where many stair designs fall short, especially when architectural intent drives slim profiles without early structural coordination.

COMMON DESIGN MISALIGNMENTS

Some recurring issues seen across projects:

- Stair loads are assumed instead of confirmed

- Barrier loads are underestimated in public settings

- Handrail fixings are not aligned with the load paths

- Lightweight stair systems are specified without confirming the load category.

HOW AS/NZS 1170 DEFINES LOADS BASED ON INTENDED USE

Compliance with AS/NZS 1170 ensures structures and access systems are designed for how they will actually be used over their working life.

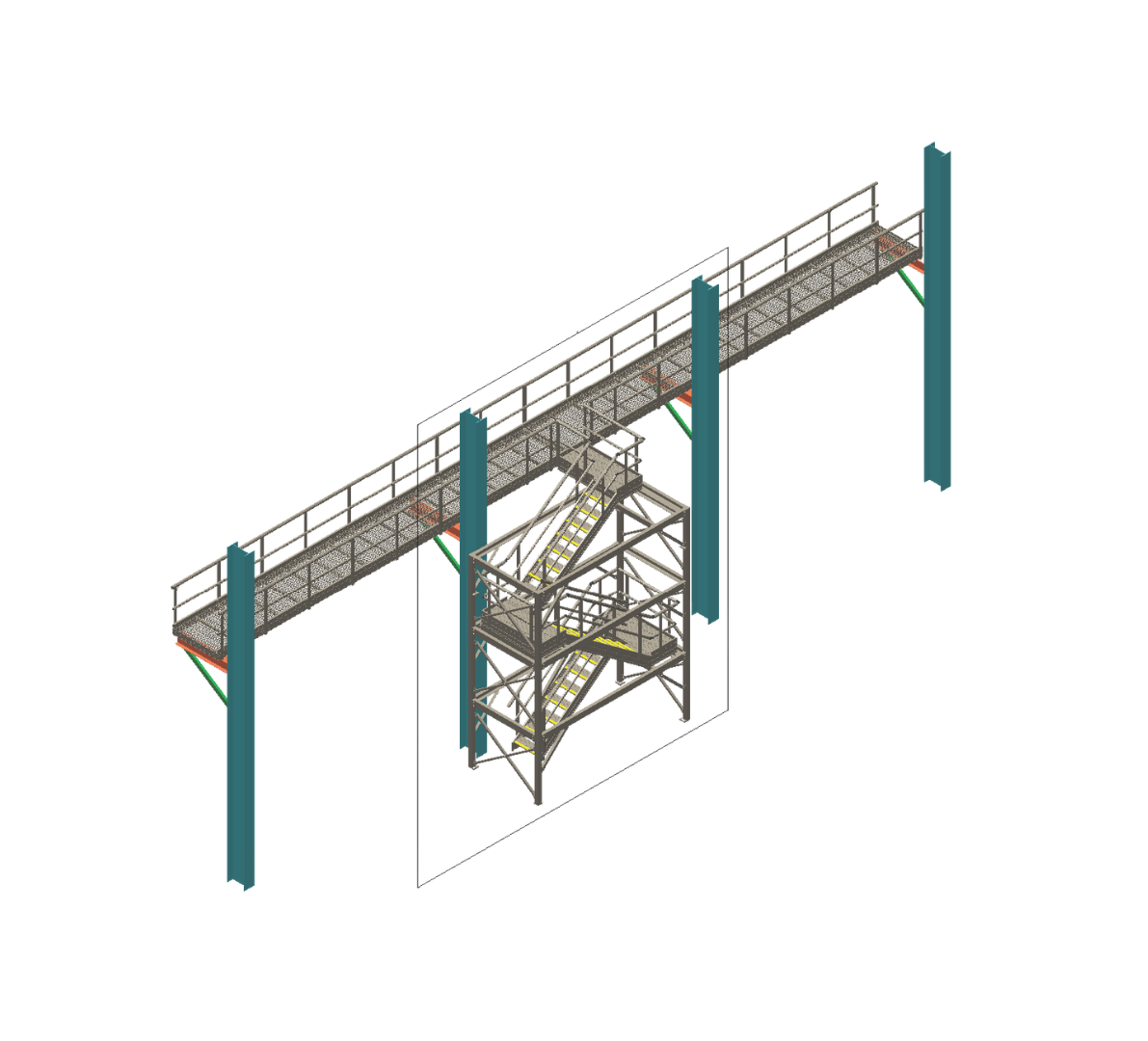

The standard focuses on identifying the correct loads for each application, based on the people, equipment, and activities the system is expected to support. This applies directly to stairs, platforms, plant decks, ladders, and roof access systems.

A plant deck supporting fixed mechanical equipment will attract a very different load profile than a stair used as a public egress route or a ladder accessed occasionally for maintenance. AS/NZS 1170 requires these differences to be clearly understood and engineered into the system from the outset.

DESIGNING FOR BOTH DEAD LOAD AND LIVE LOAD

One of the core principles of AS/NZS 1170 is separating and correctly accounting for:

- Dead loads - self-weight of the structure and any permanently installed equipment

- Live loads - people accessing the system, movement, tools, and carried materials

For example, a plant platform must be engineered not only for the weight of the installed HVAC equipment, but also for technicians walking, working, and carrying tools during maintenance.

Stairs and access platforms should safely support repeated foot traffic over time, not just occasional use.

ANALYSE THE INTENDED USE OF ACCESS SYSTEMS

AS/NZS 1170 places strong emphasis on intended use, not assumed use.

This means assessing:

- How often will the system be accessed

- How many people may be on it at once

- Whether equipment or materials will be carried

- Whether loads are evenly distributed or concentrated

Stairs, platforms, ladders, roof hatches, and plant decks all behave differently under load. The standard ensures each system is designed to withstand the worst credible load scenario, not just day-to-day operation. It is particularly important for cyclonic areas.

ENGINEERING CAPACITY AND LOAD TRANSFER

Designing for AS/NZS 1170 also involves ensuring loads are safely transferred into the supporting structure.

In some cases, this requires:

- Additional structural framing

- Load transfer beams or brackets

- Reinforced fixings into slabs, steel, or the primary structure

This approach ensures loads are not concentrated at weak points and that the system performs reliably throughout its service life.

DESIGNING FOR THE FULL LIFE OF THE SYSTEM

It requires designers and engineers to consider the entire lifespan of the product, including future maintenance, upgrades, and changes.

When load capacity is properly designed upfront, access systems remain functional, compliant, and durable without needing retrofits or operational restrictions later.