How Height Safety Is Evolving:

7 Trends to Consider

What’s shaping the future of working at heights across Australian industries

As we step into 2025, the demands around workplace safety - particularly height safety - are evolving faster than ever.

From regulatory shifts to the adoption of new technologies, the industry is seeing a clear move toward smarter systems, higher compliance expectations, and more tailored, site-specific solutions.

At Safetylyne, we work closely with project managers, engineers, asset owners, and OHS professionals across Australia.

Here are the key trends we’re seeing in height safety this year:

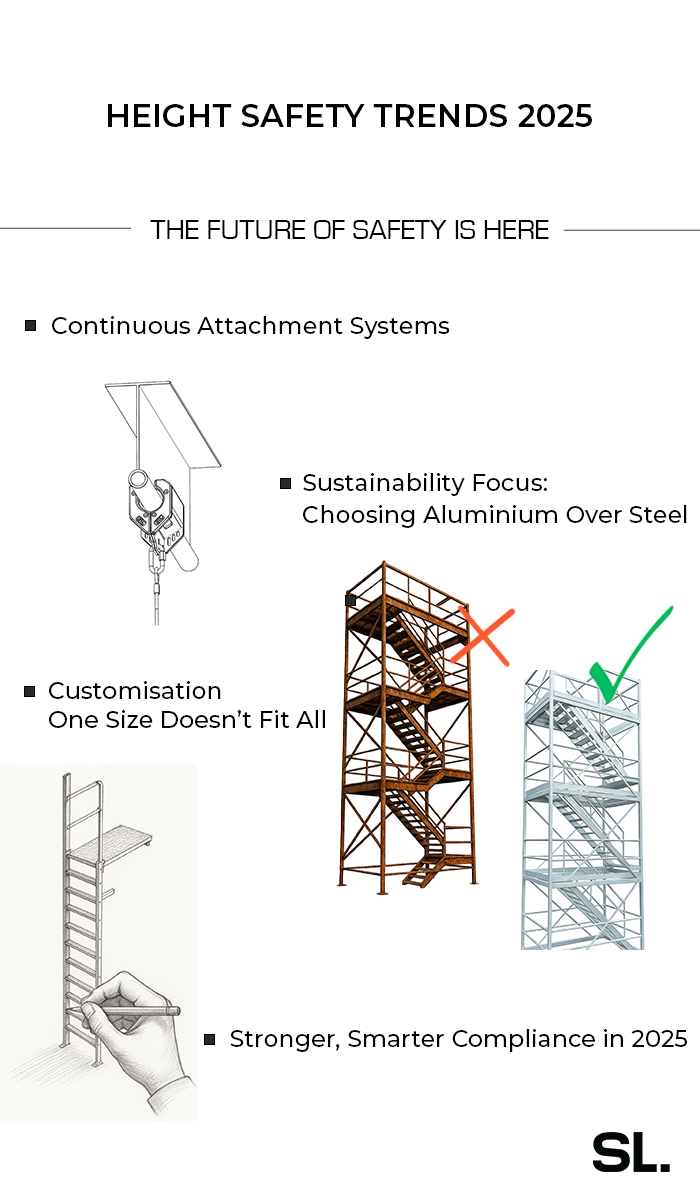

1. Shift Toward Engineered, Site-Specific Solutions

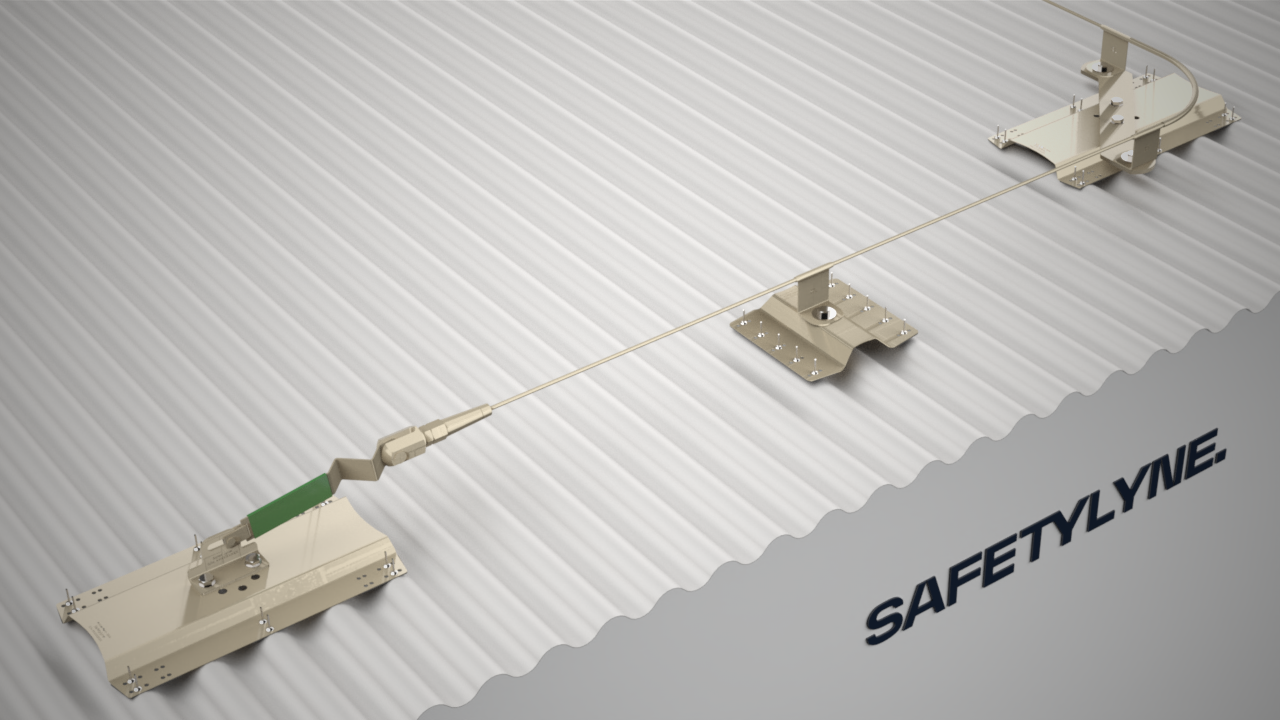

Off-the-shelf safety systems are giving way to custom-designed access and fall protection solutions that are tailored to complex structures and use cases.

Whether it's a suspended walkway for an aircraft hangar, or roof edge protection integrated with curved facades, engineered systems are becoming the standard - ensuring compliance, longevity, and functionality.

2. Smarter Roof Access Design with ROI in Mind

We are seeing a clear shift toward smarter, more strategic roof access planning, where safety systems are designed with both long-term use and return on investment in mind - especially when it comes to working at heights.

The traditional approach - installing the quickest or cheapest option - often leads to higher costs later.

For example, while fixed ladders with cages might meet minimum compliance, they can become impractical if access is needed for regular maintenance or equipment handling.

Today, architects, building designers, facility managers, and asset owners are looking beyond short-term fixes. There’s growing demand for:

- Roof access stairs that allow for safe, hands-free movement of tools or materials

- Walkways and modular platforms designed for frequent access

- Permanent systems that reduce reliance on hired elevated work platforms (EWP) over time

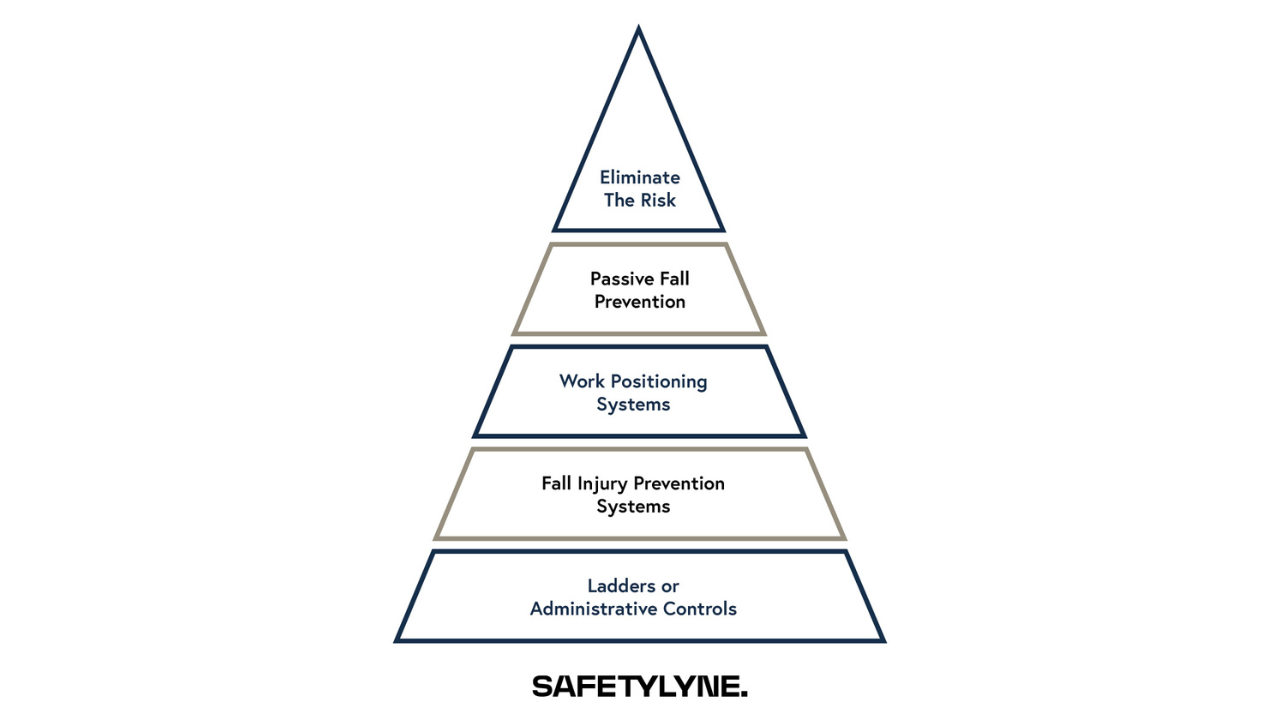

This is part of a broader move up the hierarchy of control - eliminating working at height risks wherever possible through engineered, collective protection. PPE still has its place, but it’s no longer the starting point - it’s the last layer of defence.

3. Greater Accountability and Auditing

Compliance requirements are tightening, and safety audits are becoming more rigorous. Asset managers are expected to provide documentation that shows not just installation, but ongoing inspection, maintenance, and certification of safety systems.

As a result, 2025 will see growing demand for:

- Scheduled audits and re-certifications

- Systems with long-term inspection records

- Digital recordkeeping integrated into asset management systems

4. Smarter Safety, Powered by Design

Height safety is no longer just a regulatory box to tick—it’s now part of architectural planning from the early stages. Clients are seeking solutions that:

- Integrate seamlessly into the building envelope

- Are lightweight and visually discreet (especially for heritage and commercial buildings)

- Require minimal maintenance and site disruption

Design-conscious safety is no longer a luxury - it’s an expectation.

5. Increased Use of Aluminium in Structural Safety Systems

With its corrosion resistance, light weight, and versatility, aluminium is being adopted more widely than ever for permanent access systems in 2025.

Especially for marine, industrial, and rooftop applications, aluminium platforms, stairs, ladders, and guardrails offer a long-term safety solution without the weight or rust issues of traditional materials.

6. Safety at Heights in New Sectors

Height safety is expanding beyond traditional construction and manufacturing. This year, we’re seeing increased focus in:

- Renewable energy (solar farms, wind turbines)

- Aviation and defence (aircraft maintenance access)

- Retail and hospitality (rooftop systems for maintenance and plant access)

- Healthcare and public infrastructure

Each sector brings unique challenges - requiring custom access strategies and compliant systems.

7. Consultation and Support Are Becoming the Differentiators

As systems become more complex, so do the expectations. More project managers and builders are turning to height safety specialists not just for supply - but for complete consultation, engineering, and compliance guidance.

It’s no longer just about the product. It’s about:

- Understanding the site

- Advising on the best system for the risk

- Delivering end-to-end service - from design to installation to certification

Final Thoughts

As safety standards rise and industries evolve, the future of height safety in Australia will be defined by customisation, compliance, and consultation.

At Safetylyne, we’re committed to designing and delivering access systems that not only meet standards - but exceed expectations, now and into the future.