Cooling Tower Maintenance Safety:

How to Plan, Inspect, and Stay Compliant in Australia

Why Cooling Tower Maintenance Safety Matters

Cooling towers keep HVAC and industrial systems running efficiently, but maintaining them safely can be challenging.

Workers often deal with wet surfaces, limited space, and exposure to height risks, all of which increase the chance of slips, falls, or other serious incidents.

Safe, compliant access is not just a regulatory requirement. It’s essential for protecting workers and keeping maintenance efficient.

Poorly designed or temporary access setups can slow down operations, cause equipment damage, and create avoidable hazards.

Regular inspections, proper fall protection, and permanent access systems make it easier for maintenance teams to work safely and confidently.

With the right access design, you can reduce downtime,

stay compliant with Australian standards, and create a safer environment for everyone on site.

Understanding Compliance Requirements

Cooling tower maintenance in Australia is regulated under WHS laws, which require routine inspection, cleaning, and certification.

These checks help prevent contamination, corrosion, and structural failure while keeping personnel safe during maintenance.

To stay compliant, building owners and facility managers must ensure all access systems meet AS/NZS 1657:2018, which covers the design and installation of HVAC platforms, roof ladders, access stairs, and roof walkways.

Following the

Hierarchy of Control for working at heights also plays an important role. Where possible, hazards should be eliminated or isolated before relying on personal protective equipment. You can learn more about how to apply this framework - on our

Height Safety Hierarchy page.

Common Maintenance Hazards

Cooling tower maintenance often exposes workers to several hazards:

- Slippery surfaces from water, condensation, or chemical treatments.

- Confined work zones that limit movement or equipment placement.

- Unprotected edges or inadequate guardrails near the tower perimeter.

- Corrosion and deterioration of access structures due to constant exposure to moisture and air contaminants.

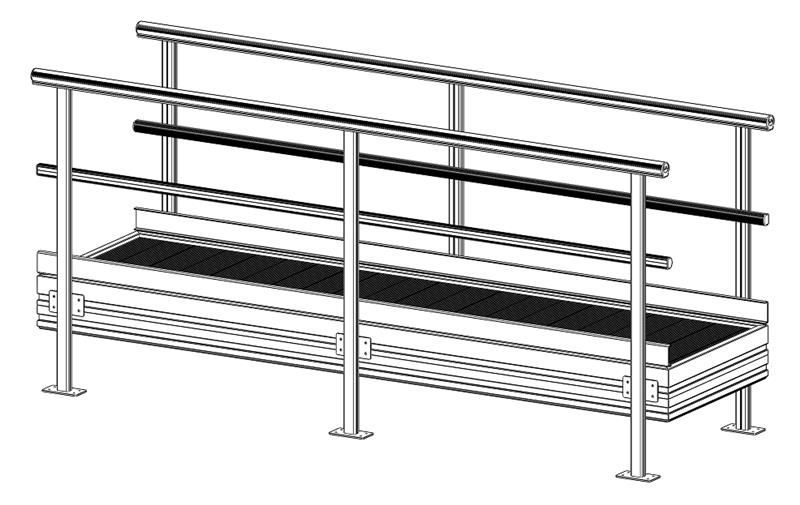

Permanent, well-designed access platforms, walkways and guardrails reduce these risks significantly.

They give maintenance teams a secure and stable working surface while keeping compliance requirements in check.

Planning Safe Access for Cooling Tower Maintenance

Before installing or upgrading access systems, start with a site assessment to identify potential fall hazards.

Review areas where workers are exposed to height risks and decide whether a fall restraint or fall arrest system is most appropriate.

Implement a routine inspection and maintenance schedule for all fall protection and access equipment.

Check for wear, corrosion, or damage, make sure every component functions correctly, and replace any faulty parts immediately.

For a professional review, talk to Safetylyne about a site safety audit.

Our team can assess your height safety setup, identify any gaps, and recommend the most effective solutions for your facility.

To summarise:

- Regular cooling tower maintenance is essential for safety and compliance.

- Permanent access systems prevent falls and reduce downtime.

- Compliance with AS/NZS 1657:2018 and WHS laws keeps facilities safe and audit-ready.

- Professional audits and tailored designs ensure each system suits your site’s exact needs.

Talk to Safetylyne about your cooling tower access or maintenance safety needs.

Our team designs, audits, and installs compliant height safety systems that protect workers and support efficient, long-term operations.