Safety Life Rail Fall Restraint

Safety Life Rails:

Continuous Fall Restraint for Secure Work at Heights

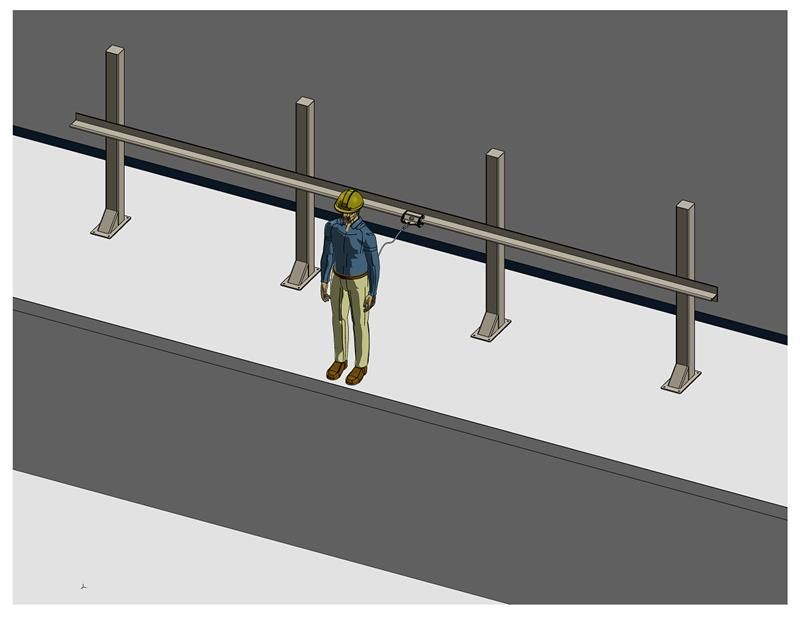

Safetylyne rail system is a reliable, unobtrusive solution for fall restraint, allowing workers to move safely along elevated areas while remaining securely connected.

This height safety system is Ideal for rooftops,

facade maintenance, and roof access. These access rails are designed to enable restrained access to routine maintenance areas or inspection on operational plants, roofs, aircraft or machinery.

Life rail systems provide continuous, hands-free fall restraint - enabling freedom of movement without compromising safety or compliance.

Life Rail - Secure, Continuous Fall Restraint for Confident Work at Heights

Working at height doesn’t need to mean working in fear.

Liferail systems for harness connection are a permanent, high-performance fall restraint solution.

These access systems have minimal deflection and allow complete freedom of movement, while keeping them securely connected at all times.

This height safety system works well for elevated work zones.

It enables safe movement along a fixed path without the need for reattachment or manual anchoring with suitable applications such as fall restraint, fall arrest, and abseil.

A correctly designed and installed life rail system reduces risk, ensures compliance, protects workers from falls, and creates peace of mind with the use of tethered restraint hardware.

Life rail systems can be set up as overhead and roof-mounted

fall restraint / arrest / abseil systems.

Life Rail Systems in Height Safety

Rigid Rail vs Other Systems

- Continuous Protection

The Life Rail continuously connects workers at all times, while allowing them to move along the rail, eliminating the need for any hook-on / hook-off methodology, maintaining a 100% connection at all times.

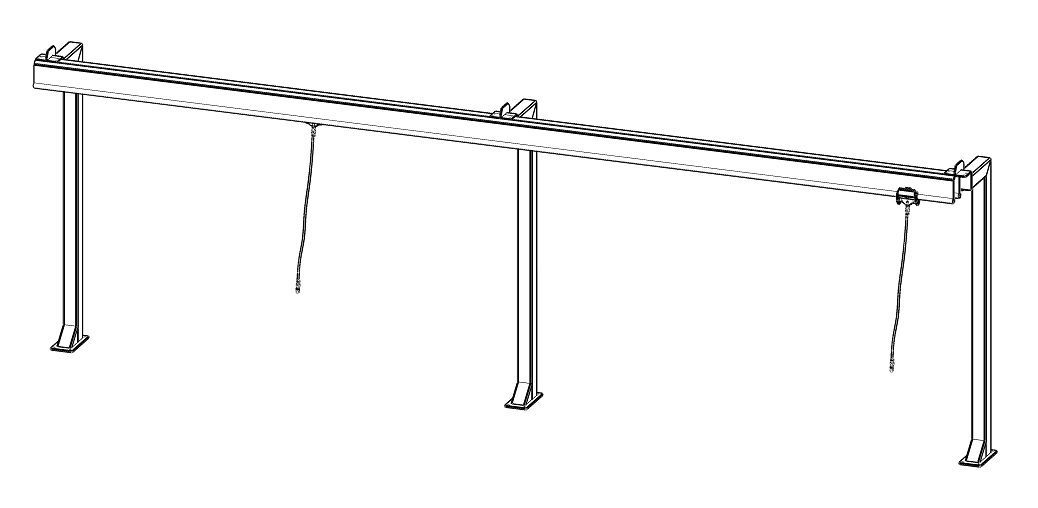

- Zero Deflection

Rail systems are becoming the preferred methodology for fall restraint applications by providing a rigid rail connection, which minimally deflects under fall restraint and arrest load, eliminating the need to consider system deflection clearances.

Simply put, a horizontal life line system will deflect between intermediate connections, which can position the user in the fall arrest zone when misused.

Traditional horizontal lifelines will deflect (or 'bow') between connections when under restraint load, creating a potential 'fall arrest zone' and requiring a larger clearance calculation. The rigid design of a life rail system eliminates this risk.

As one of our clients says:

"...Static lines have a 'rubber band' effect and require a calculated discrepancy during setup. Consideration must be given to the effects of the rubber band effect in the end stanchions of the horizontal lifeline. Rail systems solve this by remaining straight and rigid, completely eliminating deflection and any possible inaccurate assumptions...."

This zero-deflection benefit is the reason why many clients are switching to rigid rail systems for projects with limited fall clearance and reducing free-fall arrest risk.

- Custom-Built to Site Requirements

Our systems are engineered and manufactured to suit your roof structure, work zones, site layout, and the end users' needs. Including straight runs, curves, or elevation changes, which may be involved in your building design.

- Durable & Low-Maintenance

Our liferail systems use high-strength aluminium that sustains harsh Australian conditions with minimal servicing requirements. A 25-year warranty and regular inspections keep them compliant and give you lasting peace of mind.

- Discreet & Aesthetic

Designed to blend with modern architectural structures, life rails offer effective safety without compromising the visual appeal of your building.

- Certified & Compliant

Fully compliant with AS/NZS 1891 and other relevant Australian safety standards, ensuring you meet your legal obligations for working at height. These systems are adaptable to most roof and structure designs.

- Compatible with Personal

Fall Restraint Systems

Life rail systems work with standard harness and lanyard setups, allowing easy integration into existing safety protocols.

Common Applications

Where can you use Life Rail for Workers' safety?

- Rooftop maintenance zones

- Plant and equipment access platforms

- Walkways adjacent to fall edges

- Service zones near skylights or brittle surfaces

- Solar panel and HVAC servicing on roofs

- Industrial and infrastructure facilities requiring regular access

- Facade maintenance

- Machinery maintenance access

- Aircraft Hangars

- Window cleaning

- Plant assembly lines

- Wash bays

- Gantry cranes

- Aircraft platforms

Solving Real-World Problems

Frequent rooftop access is common in modern facilities, but many still rely on temporary or inconsistent fall protection methods.

This exposes workers to risk and property managers to liability.

Safety life rails are a long-term, cost-effective access solution that:

- Can reduce the need for spotter systems or scaffold setups

- Provide reliable safety even in adverse weather conditions

- Allow safe, efficient movement across large or complex rooftops

- Minimise disruption to daily operations

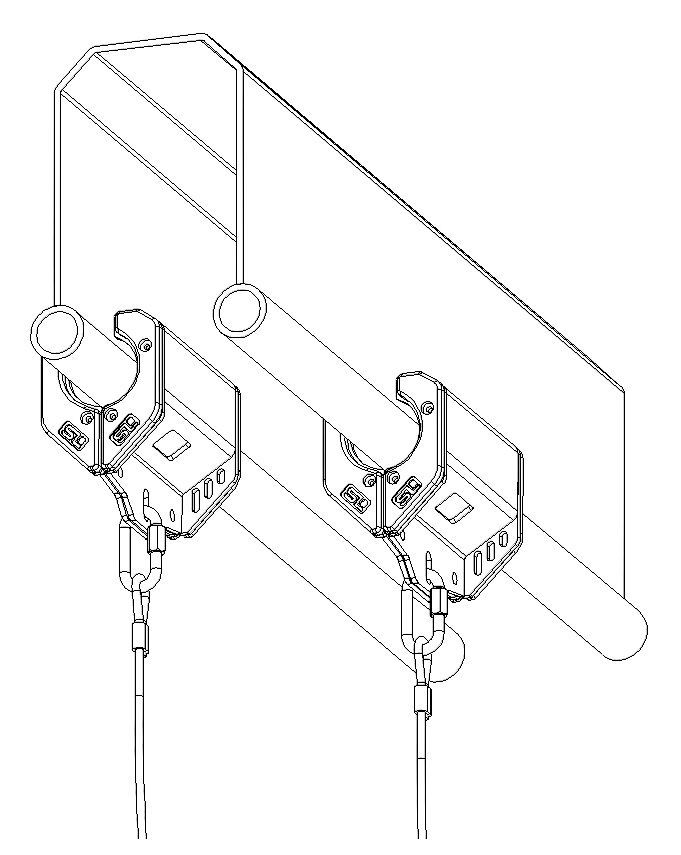

Self-Retracting Lifeline Integration

Our life rail systems can be fitted with self-retracting lifelines (SRLs) for smooth, hands-free movement in the overhead rail applications.

The SRL automatically extends and retracts as the user moves, keeping the line taut and locking instantly in the event of a fall.

This combination provides consistent protection, reduces trip hazards, and ensures compliance with Australian height safety standards.

Designed, Manufactured, and Certified in Australia

With over 25 years of experience in the height safety industry, Safetylyne designs and manufactures engineered, site-specific access and fall protection systems for Australia's most complex environments.

Our life rail systems are manufactured locally, ensuring premium quality, full traceability, and fast support when you need it.

Book a consultation today to find out how a life rail system can make your site safer, more efficient, and fully compliant.

CONTACT OUR TEAM OF ROOF SAFETY EXPERTS